Description

|

General Specifications about Solar Backsheet |

|||||||||||

|

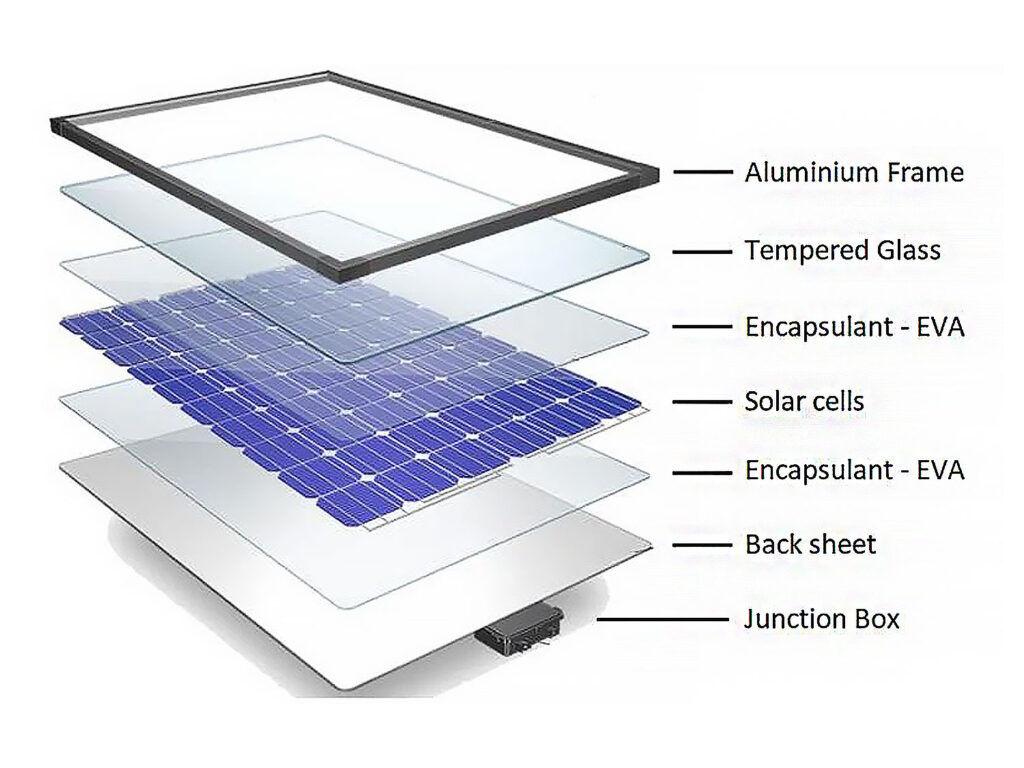

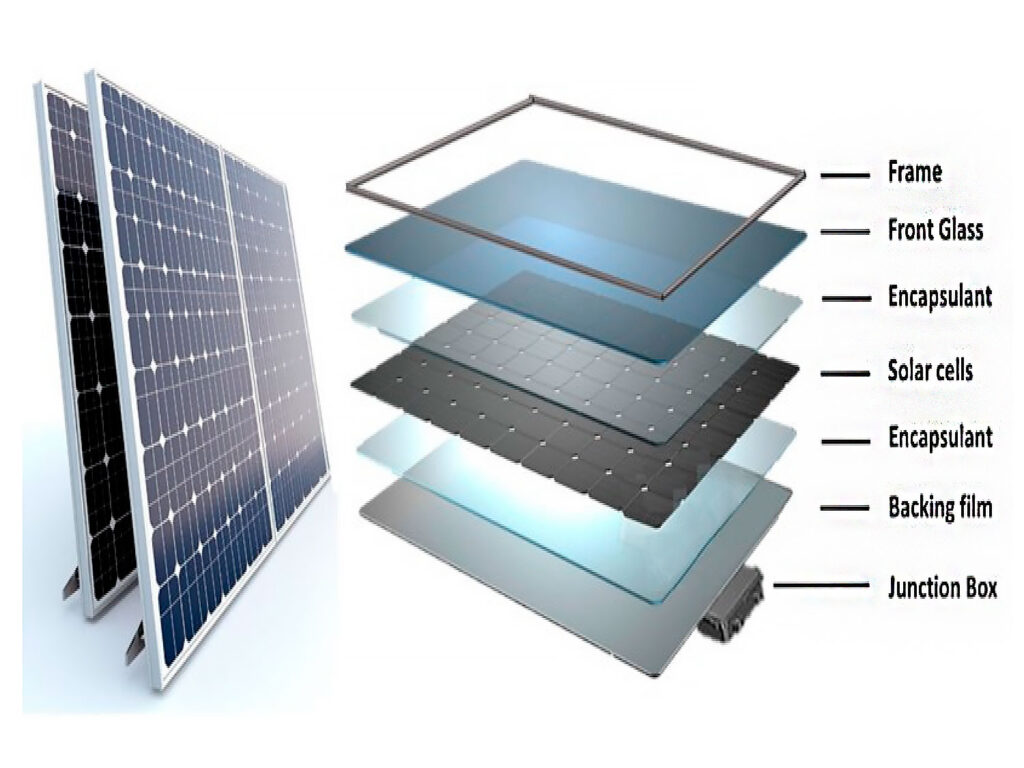

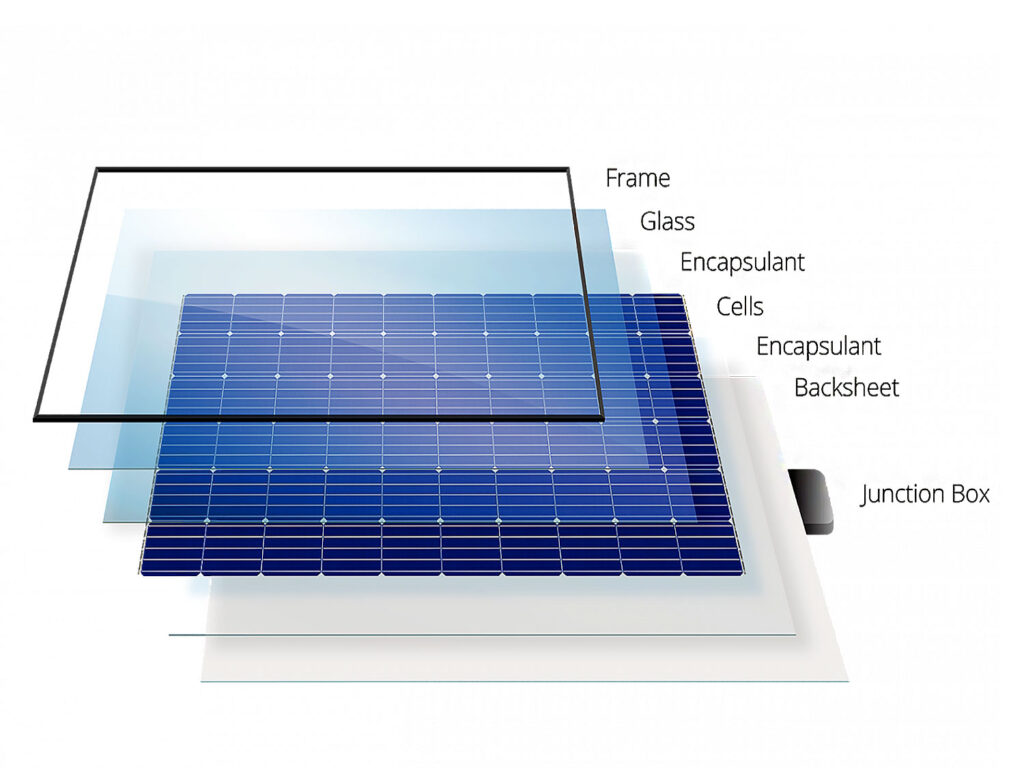

The backsheet in solar panels is the layer covering the back of the solar panel and is an important part of its structure, protecting the solar cells and internal components. |

|||||||||||

|

The most important functions of the backsheet |

|||||||||||

|

– |

Electrical insulation to protect the system from electrical leaks. |

||||||||||

|

– |

Prevents moisture penetration to protect the solar cells. |

||||||||||

|

– |

Withstands ultraviolet radiation for extended periods without deteriorating. |

||||||||||

|

– |

Improves the long-term efficiency of the solar panel. |

||||||||||

|

Common types of backsheet: |

|||||||||||

|

– |

White backsheet: Popular because it reflects heat. |

||||||||||

|

– |

Black backsheet: Used for aesthetic purposes but absorbs more heat. |

||||||||||

|

– |

Transparent backsheet: Used in some bifacial module designs. |

||||||||||

|

|

|||||||||||

|

Examples of specifications for some types of Solar Encapsulant |

|||||||||||

|

|

|||||||||||

|

Back sheet of solar panel (TYPE: RO-PET) |

|||||||||||

|

|||||||||||

|

Technical Specification |

|||||||||||

|

Properties |

Units |

Parameter |

|||||||||

|

Color |

|

White or Black |

|||||||||

|

Thickness |

mm |

320 ± 20 |

|||||||||

|

Length |

m/roll |

150 |

|||||||||

|

Width |

mm |

Customization0/+7 |

|||||||||

|

Tensile strength |

Mpa |

MD ≥100, TD≥ 100 |

|||||||||

|

Elongation at break |

Mpa |

MD ≥100, TD≥ 80 |

|||||||||

|

Heat shrink 150℃, 30Min) |

% < |

1.5 |

|||||||||

|

PVDF film/PET film peeling force |

≥ 4.0 N/cm |

||||||||||

|

BS/EVA peel strength ≥ |

60N/1.5cm |

||||||||||

|

Inner reflectance |

≥ 80% |

||||||||||

|

Falling sand test |

≥160L |

||||||||||

|

Water vapor transmission rate 38 ℃, 90% RH |

1.5g/m2 |

||||||||||

|

Breakdown voltage |

≥ 20KV |

||||||||||

|

Partial discharge |

≥ 1500 VDC |

||||||||||

|

CTI |

≥ 600V |

||||||||||

|

Thermal index TI |

120 ℃ |

||||||||||

|

Testing environment conditions: temperature 23 ± 2 ℃ , |

|||||||||||

|

Excellent properties |

|||||||||||

|

– |

Designed with a PVDF/Adh/PET/Coating Structure |

||||||||||

|

– |

Tensile Strength of ≥100 MPa and Elongation at Break ≥80% |

||||||||||

|

– |

High Breakdown Voltage of ≥18 kV and Exceptional Partial Discharge Voltage of 1000V or 1500V |

||||||||||

|

– |

Excellent Light Transmittance (≥85%) and Reflectivity (≥75%) |

||||||||||

|

– |

Outstanding Weather and Thermal Stability |

||||||||||

|

|

|||||||||||

|

Back sheet of solar panel (TYPE: PET-KPC) |

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

Technical Specification |

|||||||||||

|

Model |

Colors |

Aggregate thickness |

Breadth |

Structure |

Thickness of each layer (Standard thickness) |

||||||

|

Inshine 301Y (1000V) |

White, black |

287.5µm (0, +5%) |

≤1300mm |

PVDF//Adh//PET//Coating |

22. 5µm//10µm//250µm //5µm |

||||||

|

Inshine 301H (1500V) |

White, black |

312.5µm (0, +5%) |

≤1300mm |

PVDF//Adh//PET//Coating |

22. 5µm//10µm//250µm //5µm |

||||||

|

Inshine301Y-T (1000V) |

Transparent |

287.5µm (0, +5%) |

≤1300mm |

PVDF//Adh//PET//Coating |

22. 5µm//10µm//250µm //5µm |

||||||

|

Inshine301H-T (1500V) |

Transparent |

312.5µm (0, +5%) |

≤1300mm |

PVDF//Adh//PET//Coating |

22. 5µm//10µm//250µm //5µm |

||||||

|

|

|||||||||||

|

Test project |

Unit |

Quoted standard |

Specification value |

||||||||

|

Appearance |

— |

— |

Without impurities, bubble, fold, etc. |

||||||||

|

Tensile strength |

MPa |

GB/T 13542.2-2009 |

TD≥100; MD≥100 |

||||||||

|

Elongation at break |

% |

GB/T 13542.2-2009 |

TD≥80; MD≥100 |

||||||||

|

Hot-shrinkage rate (150°C-30min) |

% |

GB/T 13542.2-2009 |

-0.2 ≤TD ≤0.2; MD ≤0.6 |

||||||||

|

Coating adhesion |

Grade |

GB/T 9286-1998 |

Lv. 0 |

||||||||

|

Peel strength with EVA |

N/cm |

GB/T 2790-1995 |

≥60 |

||||||||

|

Breakdown voltage |

KV |

GB/T 1408.1-2016 |

≥18 |

||||||||

|

Partial discharge voltage |

VDC |

IEC 60664-1-2007 |

Inshine301Y: 1000V Inshine301H: 1500V |

||||||||

|

Water vapor transmittance 38°C-90%RH |

g/(m² day) |

GB/T 26253-2010 |

<2.0 |

||||||||

|

Volume resistivity |

Ω.CM |

GB/T 31838-2-2019 |

≥1.0*1015 |

||||||||

|

Reflectivity(400nm-1100nm) |

% |

ASTM E424-2015 |

≥75% (Write KPC) |

||||||||

|

Light transmittance (400nm-1100nm) |

% |

ASTM E424-2015 |

≥85% (Transparent KPC) |

||||||||

|

Boiling water treatment |

Appearance detection |

— |

GB/T 17748-2008 |

No delamination, no foaming, no cracking |

|||||||

|

Peel strength with EVA |

N/cm |

≥40 |

|||||||||

|

Cold and heat cycle test |

Appearance detection |

— |

IEC 61215-2-2016 |

No delamination, no foaming, no cracking |

|||||||