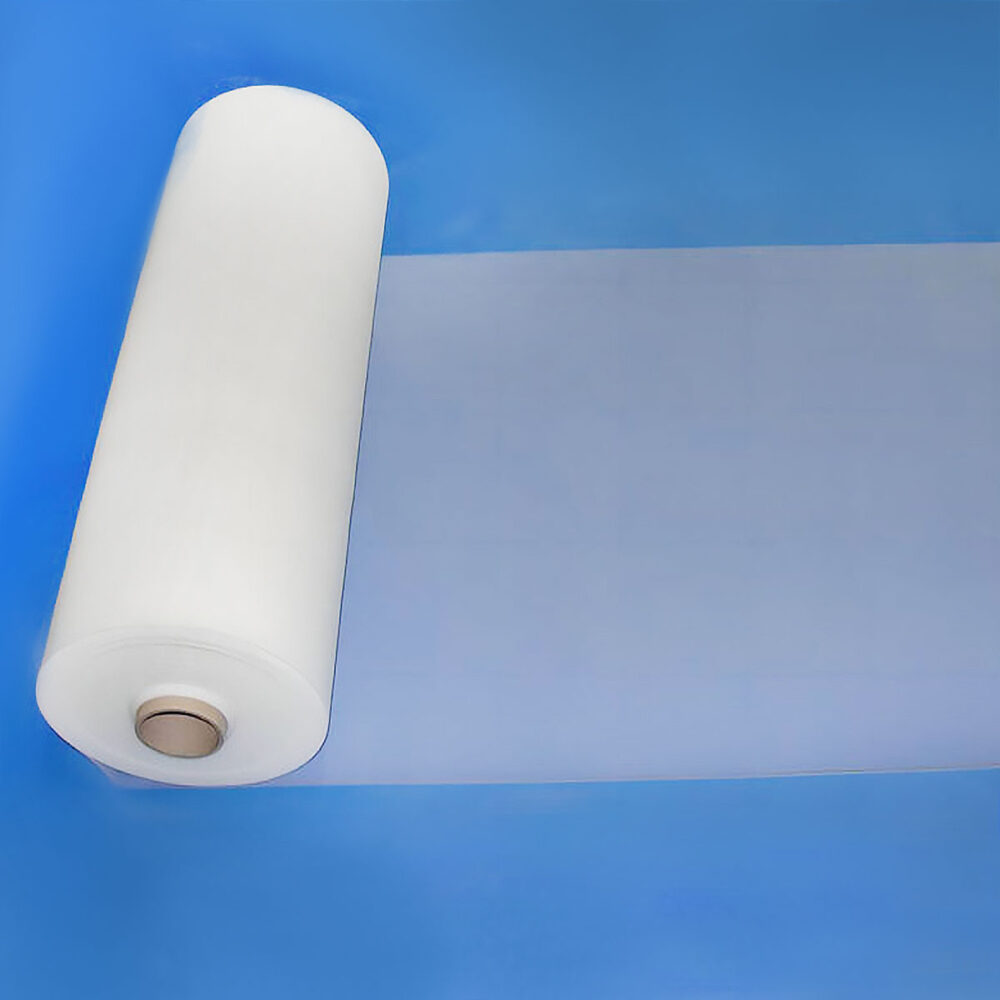

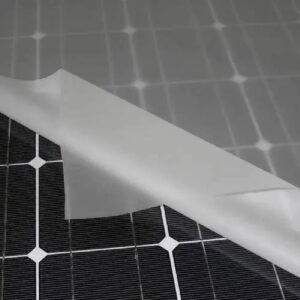

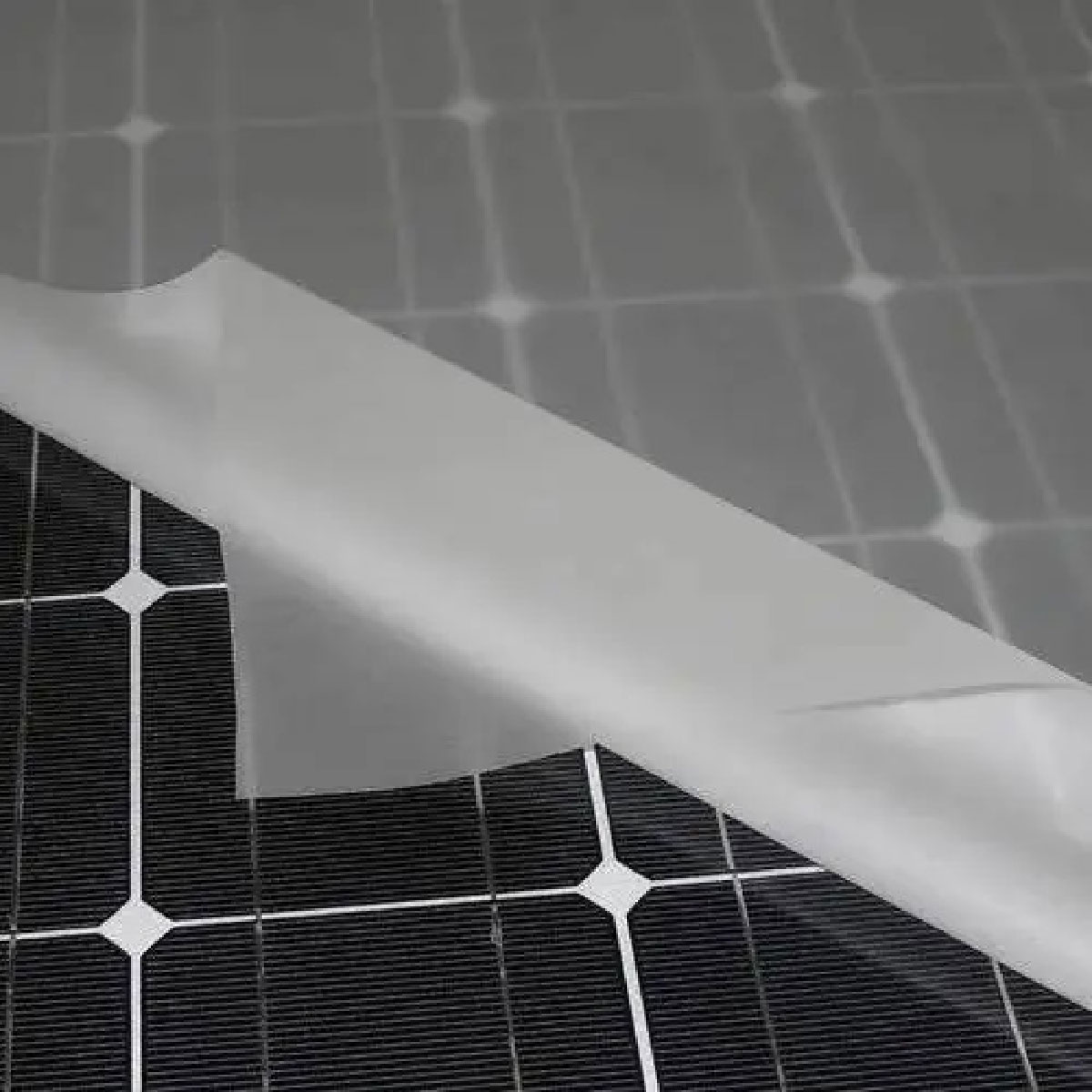

Description

|

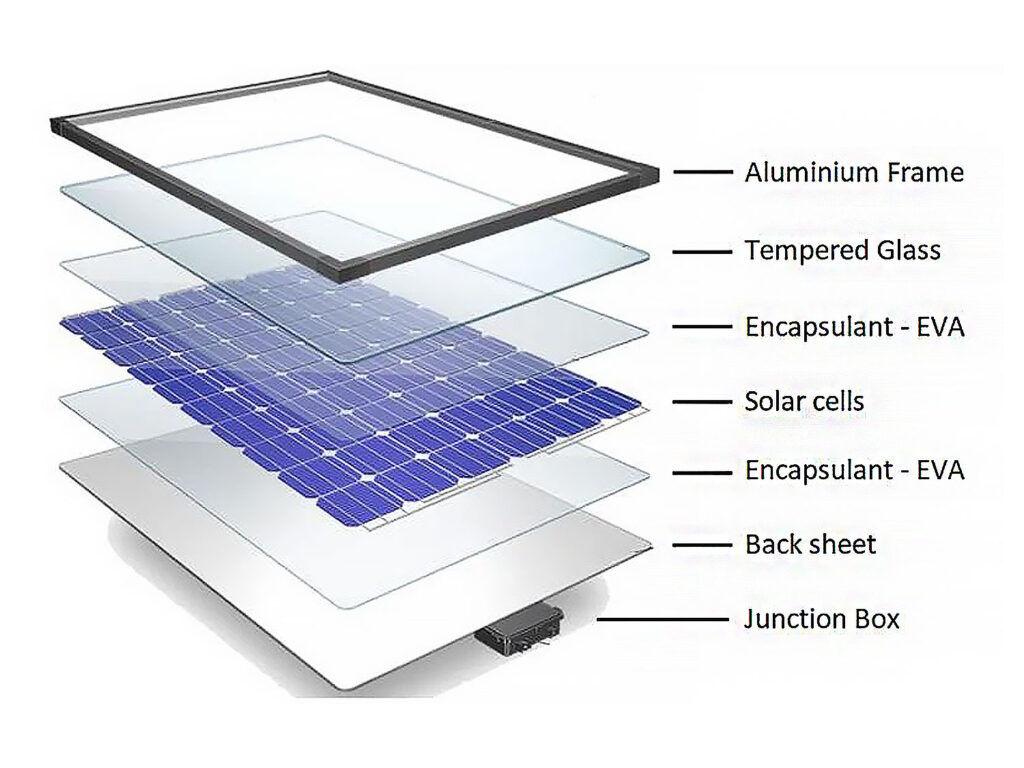

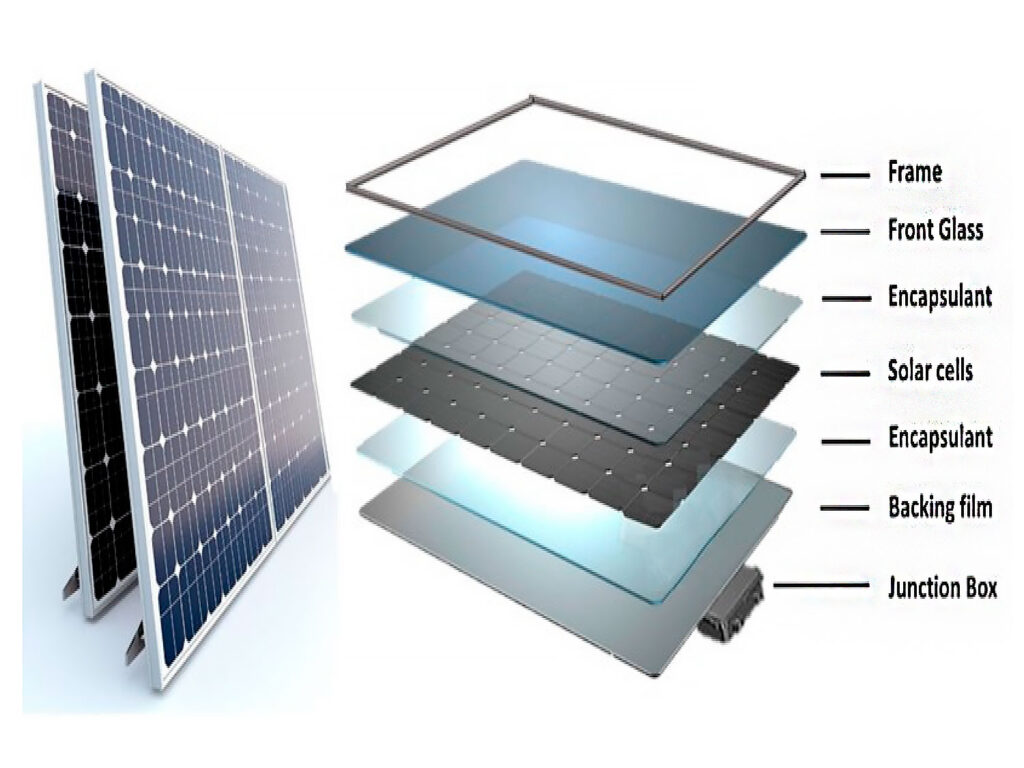

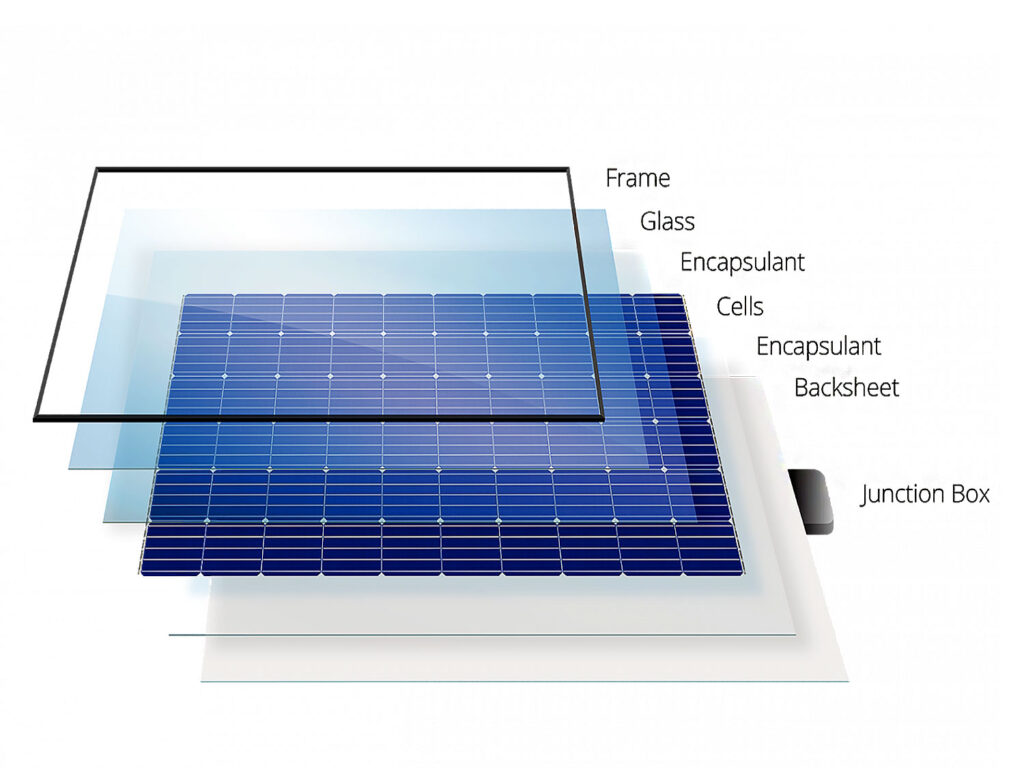

General Specifications about Solar Encapsulant |

||||||||||||

|

Its main function: |

||||||||||||

|

– |

Holds solar cells in place. |

|||||||||||

|

– |

Isolates the cells from moisture, air, and environmental factors. |

|||||||||||

|

– |

Efficiently transmits light to the cells while maintaining transparency. |

|||||||||||

|

– |

Shock absorption and protects the cells from mechanical damage. |

|||||||||||

|

Most commonly used materials: |

||||||||||||

|

– |

EVA (Ethylene Vinyl Acetate – most commonly used. |

|||||||||||

|

– |

POE (Polyolefin Elastomer) – most commonly used in bifacial panels. |

|||||||||||

|

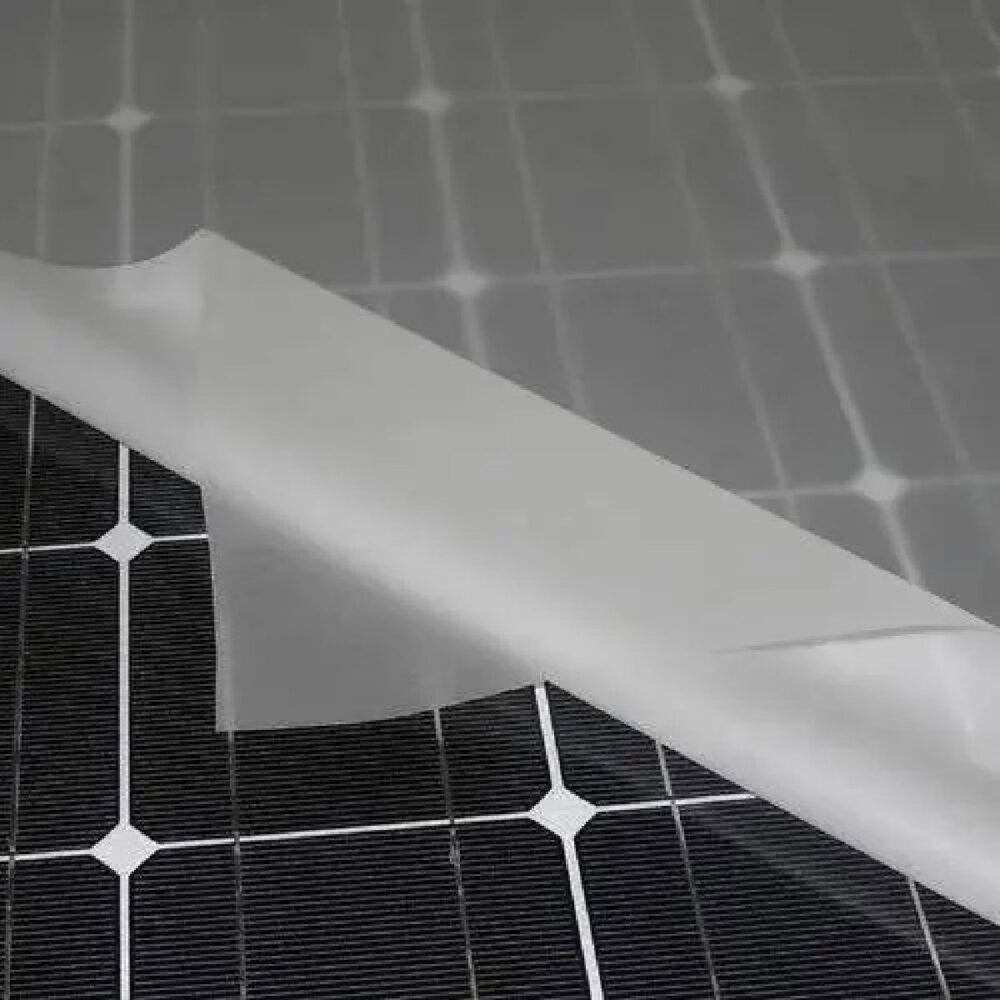

Distinctive properties: |

||||||||||||

|

– |

High transparency. |

|||||||||||

|

– |

Excellent UV resistance. |

|||||||||||

|

– |

Long-term thermal stability. |

|||||||||||

|

– |

Does not discolor or yellow over time. |

|||||||||||

|

|

||||||||||||

|

Examples of specifications for some types of Solar Encapsulant |

||||||||||||

|

|

||||||||||||

|

FY08P/ FY10P POE FILM |

||||||||||||

|

|

||||||||||||

|

|

||||||||||||

|

Technical Specification |

||||||||||||

|

Properties |

Units |

Test Method |

Parameter |

|||||||||

|

EPEU307 |

EPET306 |

|||||||||||

|

Nominal Thickness |

mm |

ASTM F2251 |

0.45~0.75 |

|||||||||

|

Unit Weight |

g/m2 |

FEIYU METHOD |

±20 |

|||||||||

|

Roll Length |

m/roll |

100/150/200 |

||||||||||

|

Width |

mm |

Customization +3 |

||||||||||

|

Density |

g/cm3 |

ASTMD792 |

0.88 |

Density |

||||||||

|

Tensile |

MD |

Mpa |

ASTM D882 |

22 |

||||||||

|

TD |

MPa |

20 |

||||||||||

|

Elongation |

MD |

% |

ASTM D882 |

500 |

||||||||

|

TD |

% |

500 |

||||||||||

|

Shrinkage Rate(120℃,3min) |

MD |

% |

ASTM D882 |

<3.0 |

||||||||

|

TD |

% |

<1.5 |

||||||||||

|

UV-Cutoff Wave Length |

nm |

~~ |

250 |

360 |

||||||||

|

Light Transmittance |

1100nm-380nm |

% |

ASTM D1003 |

>90 |

>90 |

|||||||

|

380nm-290nm |

% |

>80 |

<30 |

|||||||||

|

UV Resistance (32kWh/m2) Δb* |

~ |

ASTM G154 |

1.4 |

0.5 |

||||||||

|

UV Resistance (32kWh/m2) ΔT% |

~ |

2 |

1 |

|||||||||

|

Damp Heat Resistance (85% RH, 85°C 1000h) |

ΔY |

IEC 61215 |

<2 |

<2 |

||||||||

|

Damp Heat Resistance (85% RH, 85°C 1000h) |

ΔY |

<3 |

<3 |

|||||||||

|

Gel Content |

% |

>75 |

Gel Content |

|||||||||

|

Volume Resistivity |

Ω.cm |

ASTM D257 |

>1*1017 |

Volume Resistivity |

||||||||

|

Peeling Strength from Glass |

N/cm |

ASTM D903 |

>80 |

Peeling Strength from Glass |

||||||||

|

Peeling Strength from BS |

N/cm |

ASTM D903 |

>80 |

|||||||||

|

Water Absorption |

wt% |

ASTM D570 |

0.12 |

|||||||||

|

Inner Packing & Shift Life |

~ |

~ |

Plastic Bag, 9 |

Inner Packing & Shift Life |

||||||||

|

Nominal Temperature:145-150℃ |

||||||||||||

|

Platen Tamperature:143-153℃ |

||||||||||||

|

Vacuum Range:<60mba |

||||||||||||

|

Cure Time: 10-15 min |

||||||||||||

|

Evacuation Time:3-4min |

||||||||||||

|

Applied Bladder Pressure:910mbar |

||||||||||||

|

|

||||||||||||

|

EPE (EVA-POE-EVA) FILM EPEU307 & EPET306 GRADES |

||||||||||||

|

|

||||||||||||

|

|

||||||||||||

|

Technical Specification |

||||||||||||

|

Properties |

Units |

Test Method |

Parameter |

|||||||||

|

EPEU307 |

EPET306 |

|||||||||||

|

Total Thickness (Tolerance: ±0.05%) |

mm |

UPS method |

0.40 ~ 0.90 |

|||||||||

|

Total Width |

mm |

Scale |

Up to 1300 |

|||||||||

|

Thermal Shrinkage (MD) |

% |

On solar glass (5 min, 125OC) |

≤ 3 |

≤ 3 |

||||||||

|

Water Vapor Transmission |

g/m2 /24h |

ASTM F1249 |

≤ 5 |

≤ 5 |

||||||||

|

UV Resistance (120kWh/m2) |

ΔYI |

ASTM G154 |

≤ 5 |

≤ 5 |

||||||||

|

Humidity and Heat Resistance |

ΔYI |

ASTM E313 |

≤ 5 |

≤ 5 |

||||||||

|

Degree of Cross-linking (Gel Content) |

% |

Soxhlet Method Lamination (14 min,145OC) |

≥ 70 |

≥ 70 |

||||||||

|

Adhesion to Glass (With Backsheet) |

N/㎝ |

ASTM D 903 |

≥ 60 |

≥ 60 |

||||||||

|

Adhesion to Backsheet |

N/㎝ |

ASTM D 903 |

≥ 60 |

≥ 60 |

||||||||

|

Ultimate Elongation (Cured) |

% |

ASTM D 638 |

≥ 500 |

≥ 500 |

||||||||

|

Tensile Strength (Cured) |

MPa |

ASTM D 638 |

≥ 10 |

≥ 10 |

||||||||

|

Optical Transmittance (380nm-1100nm) |

% |

ASTM D1003 |

≥ 90 |

≥ 90 |

||||||||

|

UV Cut-off Wave Length (290nm-380nm) |

% |

ASTM D1003 |

≤ 30 |

≥ 70 |

||||||||

|

Component Power Loss |

% |

IEC G2804 |

≤ 5 |

≤ 5 |

||||||||

|

Dielectric Strength |

kV/mm |

ASTM D149 |

≤ 28 |

≤ 28 |

||||||||

|

Volume Resistivity (Cured) |

Ω*cm |

ASTM D 257 |

≥ 1*1016 |

≥ 1*1016 |

||||||||

|

Lamination Recipe |

||||||||||||

|

Lamination Parameters |

Unit |

Single Chamber |

Double Chamber |

|||||||||

|

Temperature |

OC |

145 – 150 |

145 – 150 |

|||||||||

|

Vaccum Time |

min |

4 – 6 |

4 – 6 |

|||||||||

|

Lamination Time |

min |

8 – 12 |

8 – 12 |

|||||||||

|

|

||||||||||||

|

Comparison between EVA and POE in Solar |

||||||||||||

|

Feature |

EVA (Ethylene Vinyl Acetate) |

POE (Polyolefin Elastomer) |

||||||||||

|

Market Presence |

Very common, used in over 70% of modules |

Less common, but gaining popularity |

||||||||||

|

Transparency |

High |

High |

||||||||||

|

Moisture Resistance |

Moderate |

Very high |

||||||||||

|

Thermal Stability |

Good |

Better than EVA |

||||||||||

|

Chemical Resistance |

Acceptable |

Excellent |

||||||||||

|

Suitability for Bifacial Modules |

Not ideal due to light absorption |

Excellent, allows more light |

||||||||||

|

Yellowing Over Time |

Higher tendency |

Lower tendency |

||||||||||

|

Cost |

Lower |

Slightly higher |

||||||||||