Description

|

|

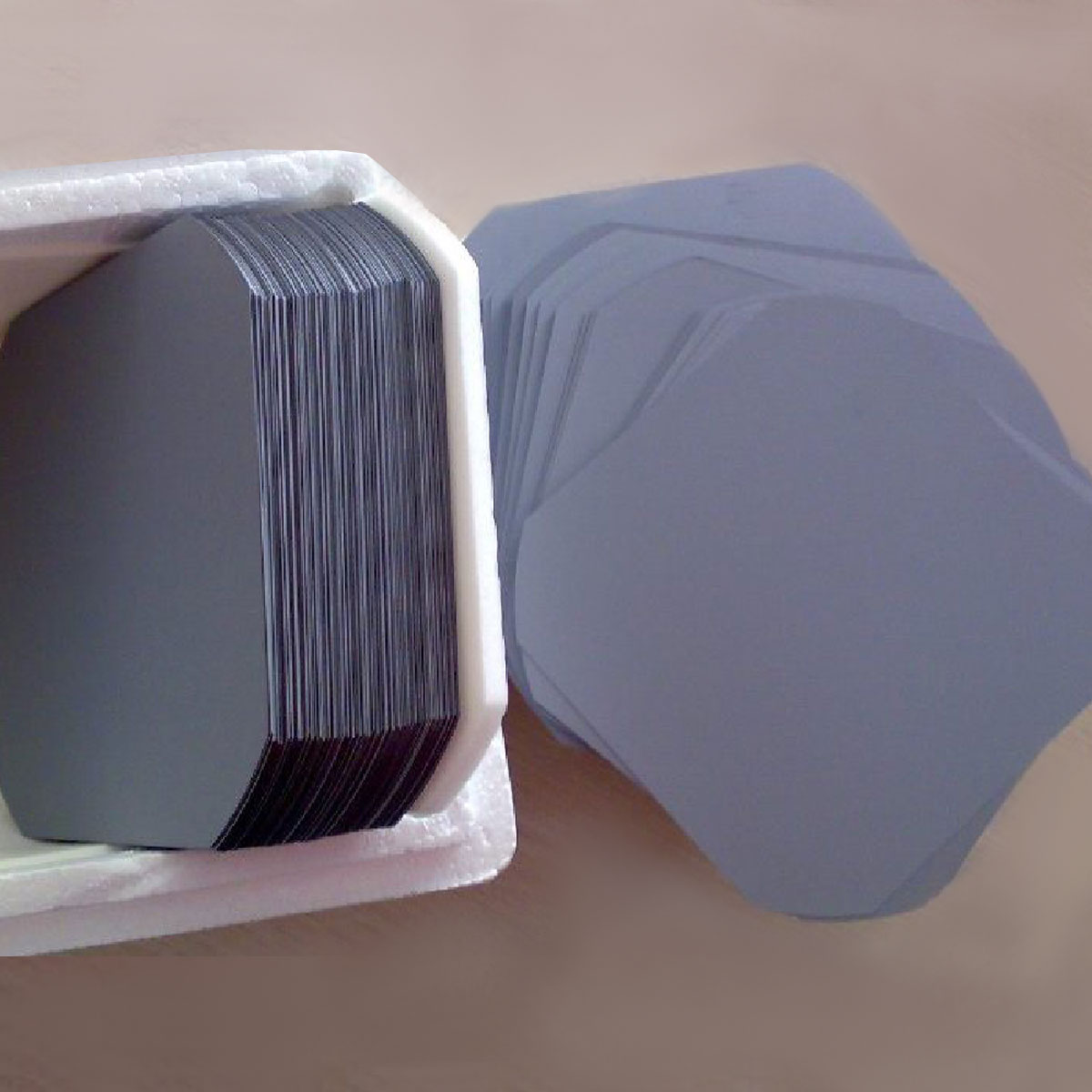

General Specifications about Solar Wafer |

||||||

|

|

Types of Solar Wafers: |

||||||

|

|

– |

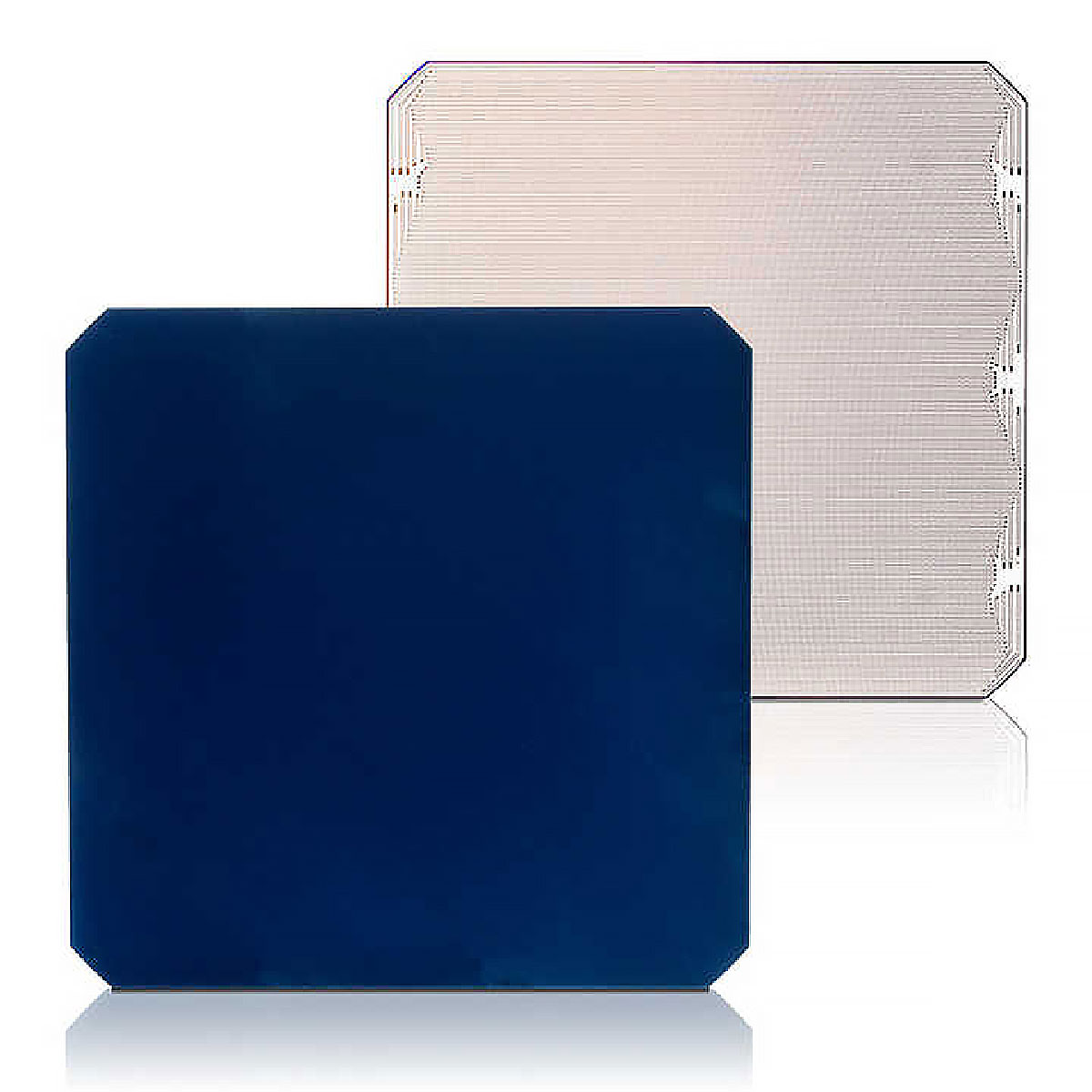

Monocrystalline: |

|||||

|

|

Cut from a single, continuous crystal of silicon, offering higher efficiency due to a uniform crystal structure. |

||||||

|

|

– |

Polycrystalline: |

|||||

|

|

|

Made from multiple silicon crystals, generally less expensive but with slightly lower efficiency. |

|||||

|

|

Common Wafer Sizes: |

||||||

|

|

– |

156.75mm x 156.75mm (M2): |

|||||

|

|

– |

A widely used size, but some manufacturers are transitioning to larger formats. |

|||||

|

|

– |

158.75mm x 158.75mm (G1): |

|||||

|

|

– |

A popular size due to compatibility with existing module designs. |

|||||

|

|

– |

166mm x 166mm (M6): |

|||||

|

|

– |

A larger wafer size, gaining traction in the market. |

|||||

|

|

– |

182mm x 182mm (M10): |

|||||

|

|

– |

Another larger format, offering higher power output. |

|||||

|

|

– |

210mm x 210mm (G12): |

|||||

|

|

– |

A large format wafer designed for increased power generation and system efficiency. |

|||||

|

|

Key Specifications: |

||||||

|

|

– |

Material: Monocrystalline or Polycrystalline silicon. |

|||||

|

|

– |

Size: Can range from 156mm to 210mm (or larger). |

|||||

|

|

– |

Thickness: Typically, around 150-200 micrometers (µm). |

|||||

|

|

– |

Resistivity: Measured in ohm-centimeters (Ω·cm), typically between 0.4 and 2.0 Ω·cm. |

|||||

|

|

– |

Lifetime: Minority carrier lifetime, measured in microseconds (µs), affects cell efficiency. |

|||||

|

|

– |

Oxygen and Carbon Concentration: Impurity levels that can impact performance. |

|||||

|

|

– |

Orientation: Crystalline orientation, often <100> ±3°. |

|||||

|

|

– |

TTV (Total Thickness Variation): Measures thickness uniformity. |

|||||

|

|

– |

Saw Mark Depth: Indicates the quality of the cutting process. |

|||||

|

|

– |

Warp and Bow: Measures flatness, with lower values indicating better quality. |

|||||

|

|

Wafer properties: |

||||||

|

|

– |

Made of pure silicon (either monocrystalline or polycrystalline). |

|||||

|

|

– |

Its thickness is typically between 120 and 200 micrometers. |

|||||

|

|

– |

It is electrically and optically processed to convert sunlight into electrical current. |

|||||

|

|

– |

Note: Wafer technologies have evolved in recent years to become thinner and more efficient, helping improve solar panel performance and reduce production costs |

|||||

|

|

These specifications may vary slightly depending on the manufacturer, customer requirements, and cell design (e.g., PERC, TOPCon, HJT). |

||||||

|

|

|

||||||

|

|

Typical Specification of Monocrystalline Silicon Solar Wafers |

||||||

|

|

Parameter |

Specification |

|||||

|

|

Material |

Monocrystalline Silicon |

|||||

|

|

Crystal Orientation |

⟨100⟩ or ⟨111⟩ |

|||||

|

|

Doping Type |

p-type (Boron) or n-type (Phosphorus) |

|||||

|

|

Resistivity |

0.5 – 3 Ω·cm (for p-type) or 1 – 10 Ω·cm (n-type) |

|||||

|

|

Wafer Size |

156.75 mm × 156.75 mm (6-inch standard) |

|||||

|

|

Wafer Thickness |

160 – 180 μm |

|||||

|

|

Surface Texture |

Pyramidal (acid or alkali etched) |

|||||

|

|

Edge |

Rounded corners (pseudo-square shape) |

|||||

|

|

TTV (Total Thickness Variation) |

< 20 μm |

|||||

|

|

Saw Damage |

Removed (via surface etching) |

|||||

|

|

Lifetime (Minority Carrier) |

> 1 μs (depends on quality grade) |

|||||

|

|

Oxygen Content |

< 1e18 atoms/cm³ |

|||||

|

|

Carbon Content |

< 5e17 atoms/cm³ |

|||||

|

|

Warp/Bow |

< 20 μm |

|||||

|

|

|

||||||

|

|

Examples of specifications for some types of Solar Wafers |

||||||

|

|

|

||||||

|

|

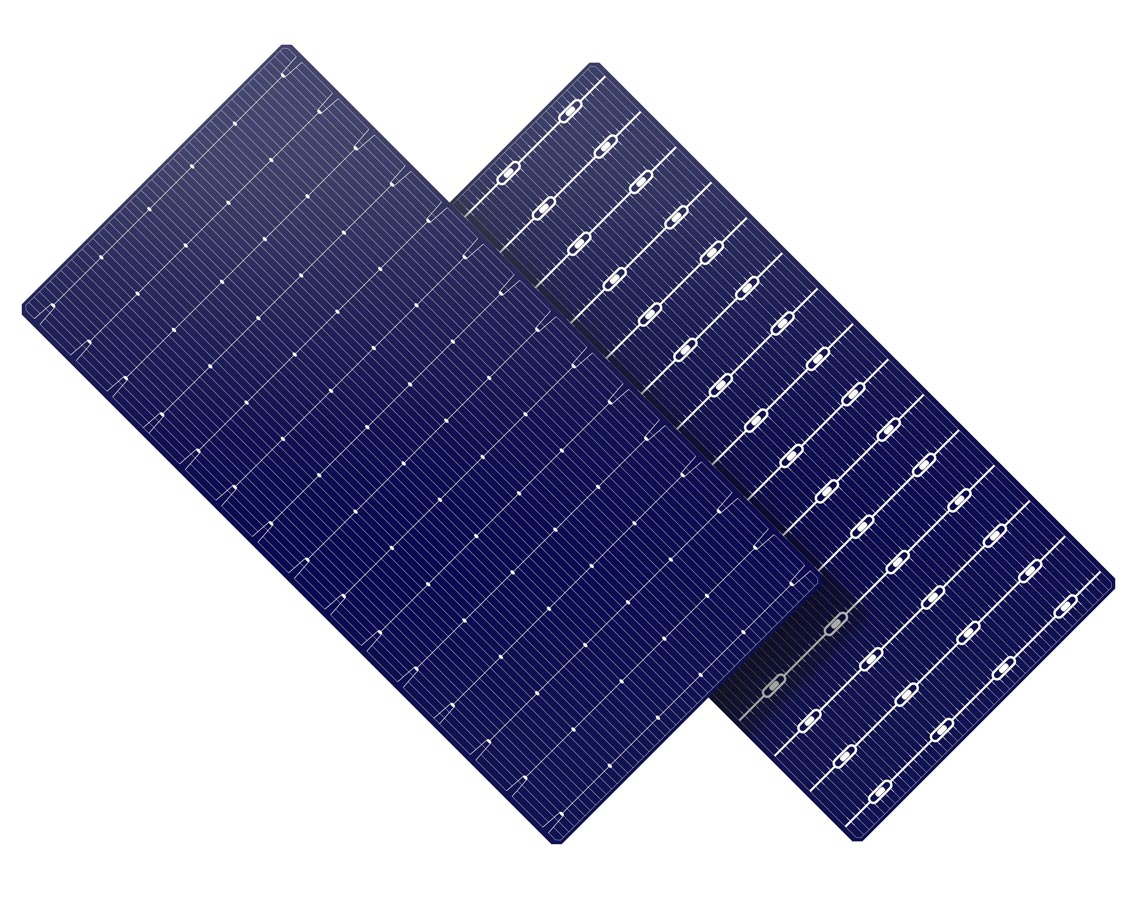

P Type 210 (Size: 210±0.25mm) |

||||||

|

|

|

||||||

|

|

|

||||||

|

|

KEY FEATURES |

||||||

|

|

– Mature process matched with advanced equipment |

||||||

|

|

– Customizable, fast delivery to meet customer needs |

||||||

|

|

– Low attenuation process |

||||||

|

|

Material properties |

||||||

|

|

Item(unit) |

Specification |

Inspection method |

||||

|

|

Conductivity Type |

P |

PN testing machine |

||||

|

|

Dopant |

Gallium |

/ |

||||

|

|

Crystallinity |

Monocrystalline |

Preferential etch techniques (ASTM F47-88) |

||||

|

|

Etch pit density (dislocation density) |

<500cm-2 |

Preferential etch techniques (ASTM F47-88) |

||||

|

|

Surface orientation |

<100>±3° |

X-ray diffraction method |

||||

|

|

Side orientation |

<010>, <001>±3° |

X-ray diffraction method |

||||

|

|

Oxygen contents (ppma) |

≤16 |

FTIR (ASTM F121-83) |

||||

|

|

Carbon contents (ppma) |

≤1 |

FTIR (ASTM F123-91) |

||||

|

|

Electrical properties |

||||||

|

|

Item(unit) |

Specification |

Inspection method |

||||

|

|

Lifetime (us) |

70 |

BCT-400 |

||||

|

|

Resistivity (Q. cm) |

0.4-1.1 |

Automatic sorting machine |

||||

|

|

Rule of geometry properties |

||||||

|

|

Item(unit) |

Specification |

Inspection method |

||||

|

|

Geometry |

Quasi square |

/ |

||||

|

|

Bevel edge shape |

Right Angle |

/ |

||||

|

|

Square length (mm) |

210±0.25mm |

Automatic sorting machine |

||||

|

|

Diagonal length (mm) |

295±0.25mm |

Automatic sorting machine |

||||

|

|

Chamfer length projection (mm) |

1.41±0.5mm |

Automatic sorting machine |

||||

|

|

Verticality |

90±0.150° |

Automatic sorting machine |

||||

|

|

Thickness(μm) |

155 + 10/ – 10 |

Automatic sorting machine |

||||

|

|

Appearance Quality |

||||||

|

|

Item(unit) |

Specification |

Inspection method |

||||

|

|

Surface quality |

No visual defects |

Automatic sorting machine |

||||

|

|

Chipping |

No visual defects, No bright line Depth<0.3mm, Length <0.5mm; Count < 2/pcs, no V-chip |

Automatic sorting machine |

||||

|

|

Saw mark (μm) |

≤15 |

Automatic sorting machine |

||||

|

|

Warpage(μm) |

≤40 |

Automatic sorting machine |

||||

|

|

TTV(μm) |

≤25 |

Automatic sorting machine |

||||

|

|

Micro cracks / Holes |

None |

Automatic sorting machine |

||||

|

|

Unfilled corner |

None |

Automatic sorting machine |

||||

|

|

|

||||||

|

|

N Type 210 (Size: 210±0.25mm) |

||||||

|

|

|

||||||

|

|

|

||||||

|

|

KEY FEATURES |

||||||

|

|

– Low Oxygen Large Heat Field Process |

||||||

|

|

– High-efficiency wafers that match customers’ differentiated needs |

||||||

|

|

– Adequate capacity reserves |

||||||

|

|

Material properties |

||||||

|

|

Item(unit) |

Specification |

Inspection method |

||||

|

|

Conductivity Type |

N |

PN testing machine |

||||

|

|

Dopant |

Phosphorus |

/ |

||||

|

|

Crystallinity |

Monocrystalline |

Preferential etch techniques (ASTM F47-88) |

||||

|

|

Etch pit density (dislocation density) |

<500cm-2 |

Preferential etch techniques (ASTM F47-88) |

||||

|

|

Surface orientation |

<100>±3° |

X-ray diffraction method |

||||

|

|

Side orientation |

<010>, <001>±3° |

X-ray diffraction method |

||||

|

|

Oxygen contents (ppma) |

≤12 |

FTIR (ASTM F121-83) |

||||

|

|

Carbon contents (ppma) |

≤1 |

FTIR (ASTM F123-91) |

||||

|

|

Electrical properties |

||||||

|

|

Item(unit) |

Specification |

Inspection method |

||||

|

|

Lifetime (us) |

>800 |

BCT-400 |

||||

|

|

Resistivity (Q. cm) |

0.3-2.1 |

Automatic sorting machine |

||||

|

|

Rule of geometry properties |

||||||

|

|

Item(unit) |

Specification |

Inspection method |

||||

|

|

Geometry |

Quasi square |

/ |

||||

|

|

Bevel edge shape |

Right Angle |

/ |

||||

|

|

Square length (mm) |

210±0.25mm |

Automatic sorting machine |

||||

|

|

Diagonal length (mm) |

295±0.25mm |

Automatic sorting machine |

||||

|

|

Chamfer length projection (mm) |

1.41±0.5mm |

Automatic sorting machine |

||||

|

|

Verticality |

90±0.150° |

Automatic sorting machine |

||||

|

|

Thickness(μm) |

130 + 10/ – 10 |

Automatic sorting machine |

||||

|

|

Appearance Quality |

||||||

|

|

Item(unit) |

Specification |

Inspection method |

||||

|

|

Surface quality |

No visual defects |

Automatic sorting machine |

||||

|

|

Chipping |

No visual defects, No bright line Depth<0.3mm, Length <0.5mm; Count < 2/pcs, no V-chip |

Automatic sorting machine |

||||

|

|

Saw mark (μm) |

≤15 |

Automatic sorting machine |

||||

|

|

Warpage(μm) |

≤40 |

Automatic sorting machine |

||||

|

|

TTV(μm) |

≤25 |

Automatic sorting machine |

||||

|

|

Micro cracks / Holes |

None |

Automatic sorting machine |

||||

|

|

Unfilled corner |

None |

Automatic sorting machine |

||||

|

|

|||||||

|

N Type 210 (Size: 182*183.75±0.25mm) |

|||||||

|

|

|||||||

|

|

|||||||

|

|

KEY FEATURES |

||||||

|

|

– Low Oxygen Large Heat Field Process |

||||||

|

|

– High-efficiency wafers that match customers’ differentiated needs |

||||||

|

|

– Adequate capacity reserves |

||||||

|

|

Material properties |

||||||

|

|

Item(unit) |

Specification |

Inspection method |

||||

|

|

Conductivity Type |

N |

PN testing machine |

||||

|

|

Dopant |

Phosphorus |

/ |

||||

|

|

Crystallinity |

Monocrystalline |

Preferential etch techniques (ASTM F47-88) |

||||

|

|

Etch pit density (dislocation density) |

<500cm-2 |

Preferential etch techniques (ASTM F47-88) |

||||

|

|

Surface orientation |

<100>±3° |

X-ray diffraction method |

||||

|

|

Side orientation |

<010>, <001>±3° |

X-ray diffraction method |

||||

|

|

Oxygen contents (ppma) |

≤12 |

FTIR (ASTM F121-83) |

||||

|

|

Carbon contents (ppma) |

≤1 |

FTIR (ASTM F123-91) |

||||

|

|

Electrical properties |

||||||

|

|

Item(unit) |

Specification |

Inspection method |

||||

|

|

Lifetime (us) |

>800 |

BCT-400 |

||||

|

|

Resistivity (Q. cm) |

0.3-2.1 |

Automatic sorting machine |

||||

|

|

Rule of geometry properties |

||||||

|

|

Item(unit) |

Specification |

Inspection method |

||||

|

|

Geometry |

Quasi square |

/ |

||||

|

|

Bevel edge shape |

Right Angle |

/ |

||||

|

|

Square length (mm) |

182 / 183.75±0.25mm |

Automatic sorting machine |

||||

|

|

Diagonal length (mm) |

247±0.25mm |

Automatic sorting machine |

||||

|

|

Chamfer length projection (mm) |

7.51±0.5mm |

Automatic sorting machine |

||||

|

|

Verticality |

90±0.15° |

Automatic sorting machine |

||||

|

|

Thickness(μm) |

130 + 10/ – 10 |

Automatic sorting machine |

||||

|

|

Appearance Quality |

||||||

|

|

Item(unit) |

Specification |

Inspection method |

||||

|

|

Surface quality |

No visual defects |

Automatic sorting machine |

||||

|

|

Chipping |

No visual defects, No bright line Depth<0.3mm, Length <0.5mm; Count < 2/pcs, no V-chip |

Automatic sorting machine |

||||

|

|

Saw mark (μm) |

≤15 |

Automatic sorting machine |

||||

|

|

Warpage(μm) |

≤40 |

Automatic sorting machine |

||||

|

|

TTV(μm) |

≤25 |

Automatic sorting machine |

||||

|

|

Micro cracks / Holes |

None |

Automatic sorting machine |

||||

|

|

Unfilled corner |

None |

Automatic sorting machine |

||||

|

|

|

||||||

|

|

Comparison Between |

||||||

|

|

Feature |

Monocrystalline Silicon |

Polycrystalline Silicon |

||||

|

|

Crystal Structure |

Single, continuous crystal structure |

Multiple silicon crystals fused together |

||||

|

|

Color |

Dark black or deep blue with rounded edges |

Light to medium blue with square edges |

||||

|

|

Efficiency |

Higher (typically 18–23%) |

Lower (typically 15–18%) |

||||

|

|

Performance in Low Light |

Better |

Moderate |

||||

|

|

Temperature Tolerance |

Better performance at high temperatures |

Slightly more affected by heat |

||||

|

|

Material Waste in Production |

More waste due to precise cutting of cylindrical ingots |

Less waste, simpler cutting from blocks |

||||

|

|

Lifespan |

25+ years (same as poly, but retains performance better) |

25+ years |

||||

|

|

Cost |

Higher |

Lower |

||||

|

|

Space Efficiency |

More power per square meter (ideal for limited roof space) |

Less efficient use of space |

||||

|

|

Common Applications |

Residential rooftops, commercial systems, space-constrained areas |

Utility-scale, cost-sensitive projects |

||||