Description

|

General Specifications about Solar Sealant & Adhesive |

|||

|

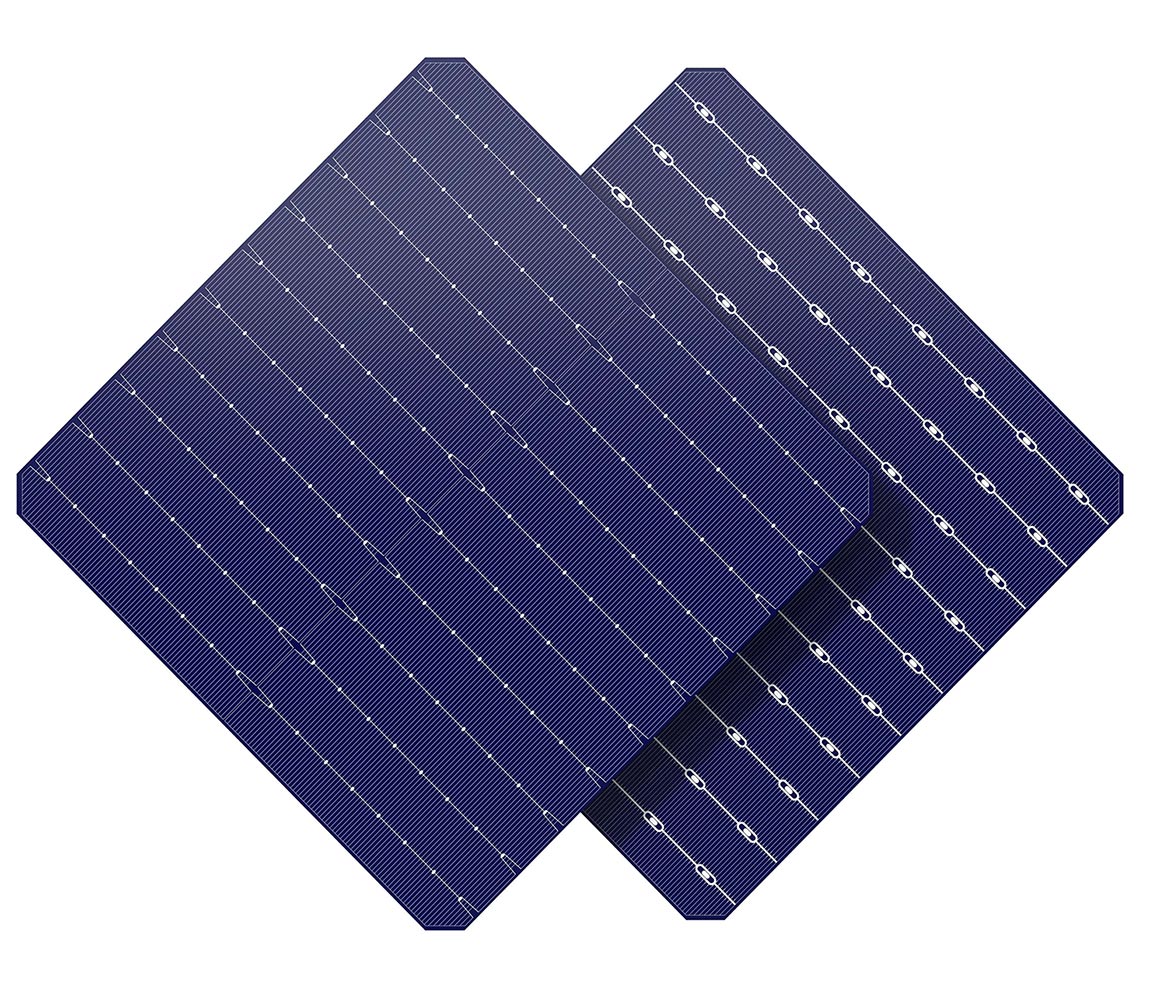

Here is a comprehensive specification sheet for Solar Sealants & Adhesives, which are used to bond and seal components in photovoltaic (PV) modules, such as the junction box, frame, backsheet, and glass, ensuring long-term durability and weather resistance. |

|||

|

Parameter |

Specification |

||

|

Type |

Silicone, Polyurethane (PU), Modified Silicone (MS), or Butyl-based |

||

|

Application Areas |

Junction box bonding, Frame sealing, Glass bonding, Backsheet lamination |

||

|

Color |

Black / White / Transparent / Grey |

||

|

Viscosity |

30,000 – 300,000 cP (depending on type; paste-like consistency) |

||

|

Curing Type |

Moisture-curing (RTV), UV-curing, or two-component (dual-cure) |

||

|

Skin-over Time |

5 – 30 minutes (at 25°C, 50% RH) |

||

|

Full Cure Time |

24 – 72 hours (varies by formulation and thickness) |

||

|

Shore A Hardness |

25 – 60 (Flexible to semi-rigid) |

||

|

Elongation at Break |

≥ 200% – 500% (high flexibility) |

||

|

Tensile Strength |

1.5 – 3.5 MPa (typical) |

||

|

Adhesion Strength |

Excellent adhesion to glass, aluminum, PET, and TPT |

||

|

Dielectric Strength |

> 20 kV/mm (essential for electrical insulation) |

||

|

Volume Resistivity |

≥ 1 × 10¹⁴ Ω·cm |

||

|

Thermal Conductivity |

~0.2 W/m·K (standard) – higher for thermal adhesives |

||

|

Temperature Resistance |

-40°C to +150°C (some up to +200°C intermittent) |

||

|

UV Resistance |

Excellent (especially in silicones and MS polymers) |

||

|

Water Resistance |

Excellent (suitable for outdoor and marine use) |

||

|

Shelf Life |

6 – 12 months (unopened, cool dry storage) |

||

|

Packaging |

300 ml cartridges, 600 ml sausages, bulk pails, or drums |

||

|

Compliance Standards |

UL 94-V0, IEC 61215, RoHS, REACH |

||

|

|

|||

|

ADCOBOND D18-221 |

|||

|

|||

|

|

|||

|

This product is a series of high-performance, pressure-sensitive, butyl tapes. The material is shaped to conform to circular or flat sections with specific dimensional tolerances. Unless otherwise specified, the material is protected on one side by a removable jaw liner. |

|||

|

Product Technical Specifications |

|||

|

Rheology |

Typical Value |

Test Method |

|

|

Specific Gravity |

1.1 |

ASTM D71 |

|

|

Cone Penetration |

85 dmm |

ASTM D217, 150g added Load |

|

|

Elongation |

800% |

ASTM D412, Die C |

|

|

Tensile Strength |

80 kPa |

ASTM D412, Die C |

|

|

Peel Adhesion |

2 N/mm |

FLTM BU 112-02, Method A |

|

|

Adhesive Strength |

1.5 N/mm |

FLTM BU 112-02, Method C |

|

|

Yield Strength |

41 kPa |

Chrysler LP463CB-10-01 |

|

|

Creep Resistance |

1.5 mm |

GM9758P |

|

|

Cold Shock Resistance |

Passes 10 slams @ -29°C (-20°F) |

GM9773P |

|

|

Fogging Resistance |

80 |

SAE J1756 |

|

|

Burn Rate |

0.99 in/min |

FMVSS 302 |

|

|

Service Temperature Range |

-40°C to 88°C (-40°F to 190°F) |

||

|

Specifications |

|||

|

Chrysler |

MS-CC-257, MS-CD-610, MS-CD-641 Type A |

||

|

Ford |

WSB-M3G210-A |

||

|

General Motors |

9984192 9985636 9985882 GMW15410 |

||

|

Nissan |

NES M 8505 |

||

|

Toyota |

TSM-1712G |

||

|

Technology |

Butyl |

||

|

Type of Product |

High Performance Tape |

||

|

Appearance / Color |

Black |

||

|

Consistency |

Tape |

||

|

Features and Benefits |

|||

|

– Excellent sealing properties |

|||

|

– Good adhesion to polar surfaces (ABS, acrylic, aluminum, glass, painted and steel substrates) |

|||

|

– Good adhesion to non-polar surfaces (EPDM, polyethylene, polypropylene and TPO substrates) |

|||

|

– Exceptional performance in low temperature environments |

|||

|

– Good heat resistance and moderate strength for bonding applications |

|||