Description

|

General Specifications about Solar Ribbon |

|||||||

|

Solar ribbons, or PV ribbons, are thin, solder-coated copper strips used to connect solar cells in a panel, with specifications varying by application, but generally including a copper base (over 99.90% pure) with good conductivity (over 99%), a tensile strength around 25 kgf/mm², and a solder coating (e.g., Sn60Pb40, Sn96.5Ag3.5) applied to a uniform thickness of 10-40 μm. Key parameters are width (1-6mm), thickness (0.08-0.5mm), and elongation (typically 15-25% minimum). |

|||||||

|

Material: |

|||||||

|

– |

Base Material: Copper, with a minimum content of 99.90% and a base copper conductivity of at least 99% IACS. |

||||||

|

|

Solder Coating: The copper is coated with a tin-lead or lead-free alloy, like Sn60/Pb40 or Sn96.5/Ag3.5. The coating thickness is typically 10-40 μm, |

||||||

|

Purity & Conductivity: |

|||||||

|

– |

Electrical conductivity ≥ 99% IACS ensuring maximum current transfer efficiency. |

||||||

|

Dimensions: |

|||||||

|

– |

Tabbing Ribbon: 1.0 – 3.0 mm width × 0.08 – 0.25 mm thickness |

||||||

|

– |

Bus Ribbon: 3.0 – 7.0 mm width × 0.20 – 0.50 mm thickness |

||||||

|

Coating Thickness: |

|||||||

|

– |

15 – 25 μm hot-dip tin coating for oxidation protection and improved solderability. |

||||||

|

Solder Alloys: |

|||||||

|

– |

Available in traditional leaded alloys (Sn63Pb37) or RoHS-compliant lead-free alloys such as SAC305 (Sn96.5Ag3Cu0.5). |

||||||

|

Mechanical Properties: |

|||||||

|

– |

Tensile Strength: ≤ 270 MPa |

||||||

|

– |

Yield Strength: ≤ 90 MPa |

||||||

|

– |

Elongation: ≥ 25% (for ribbons with width < 3 mm) |

||||||

|

Durability: |

|||||||

|

– |

Excellent resistance to oxidation, humidity, and thermal cycling to ensure long-term stability and reliability. |

||||||

|

Applications: |

|||||||

|

– |

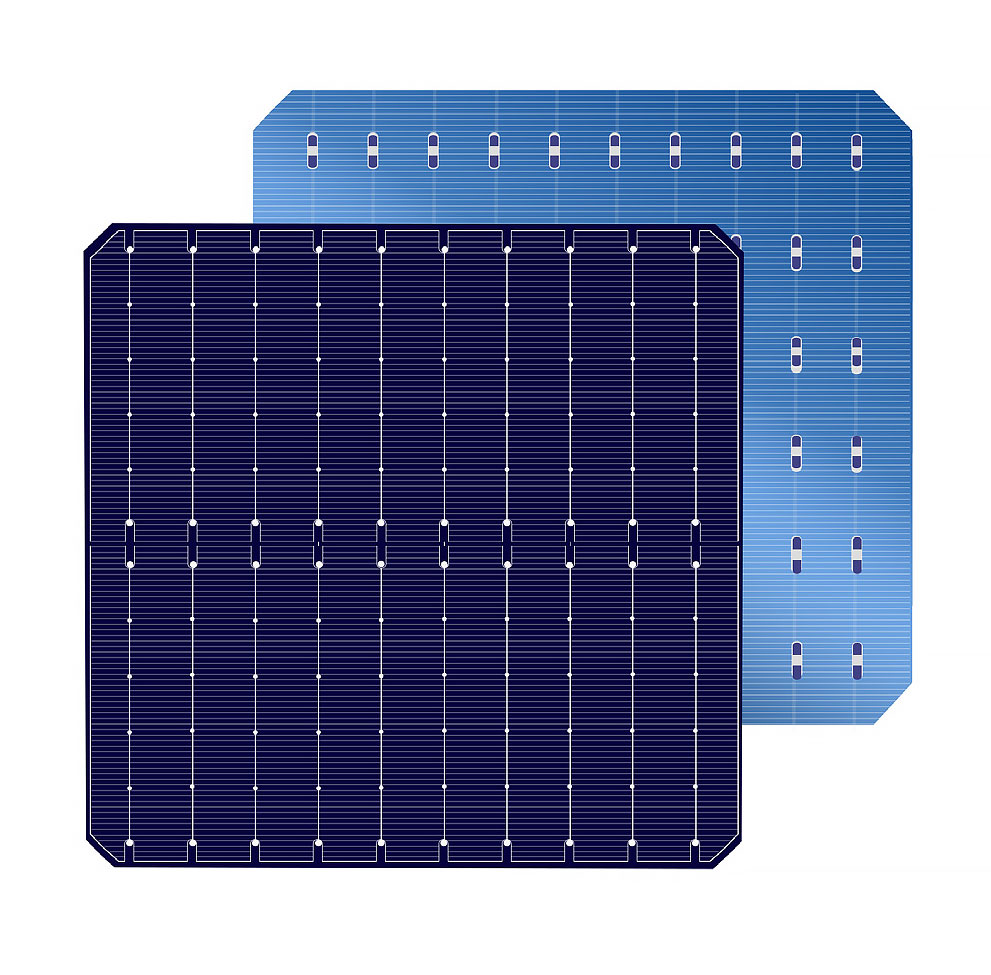

Interconnection of solar cells in photovoltaic modules |

||||||

|

– |

Current collection and transmission to busbars |

||||||

|

– |

Suitable for tabber/stringer production lines |

||||||

|

– |

Customization: Custom width, thickness, coating type, and spool size can be provided according to customer requirements |

||||||

|

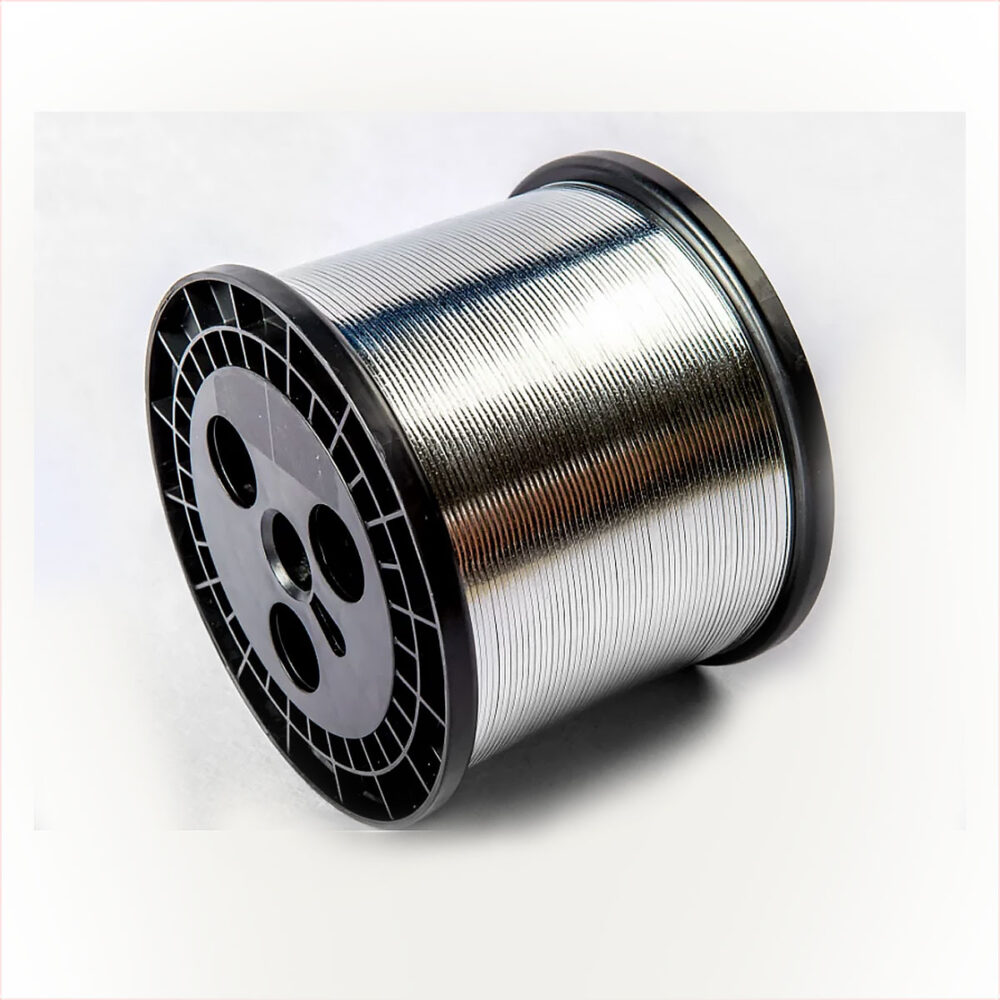

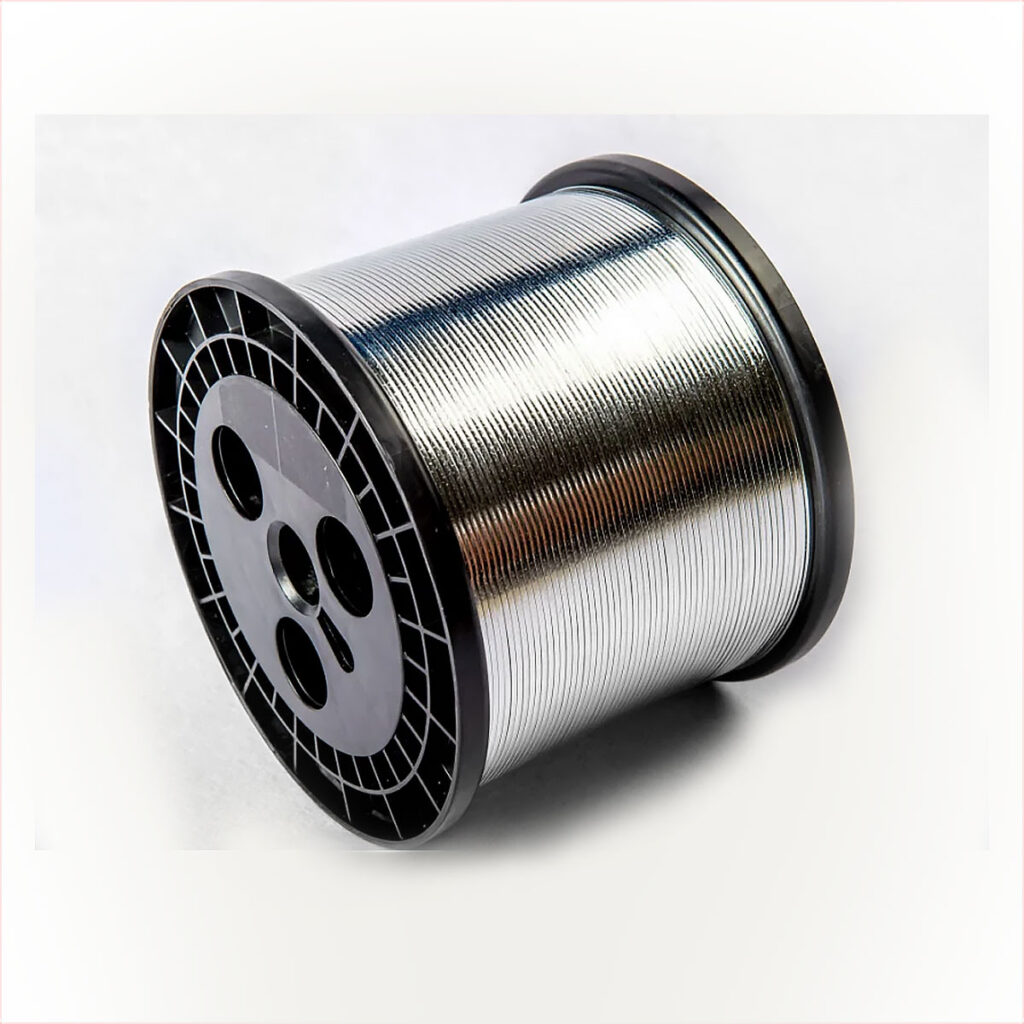

Packaging: |

|||||||

|

– |

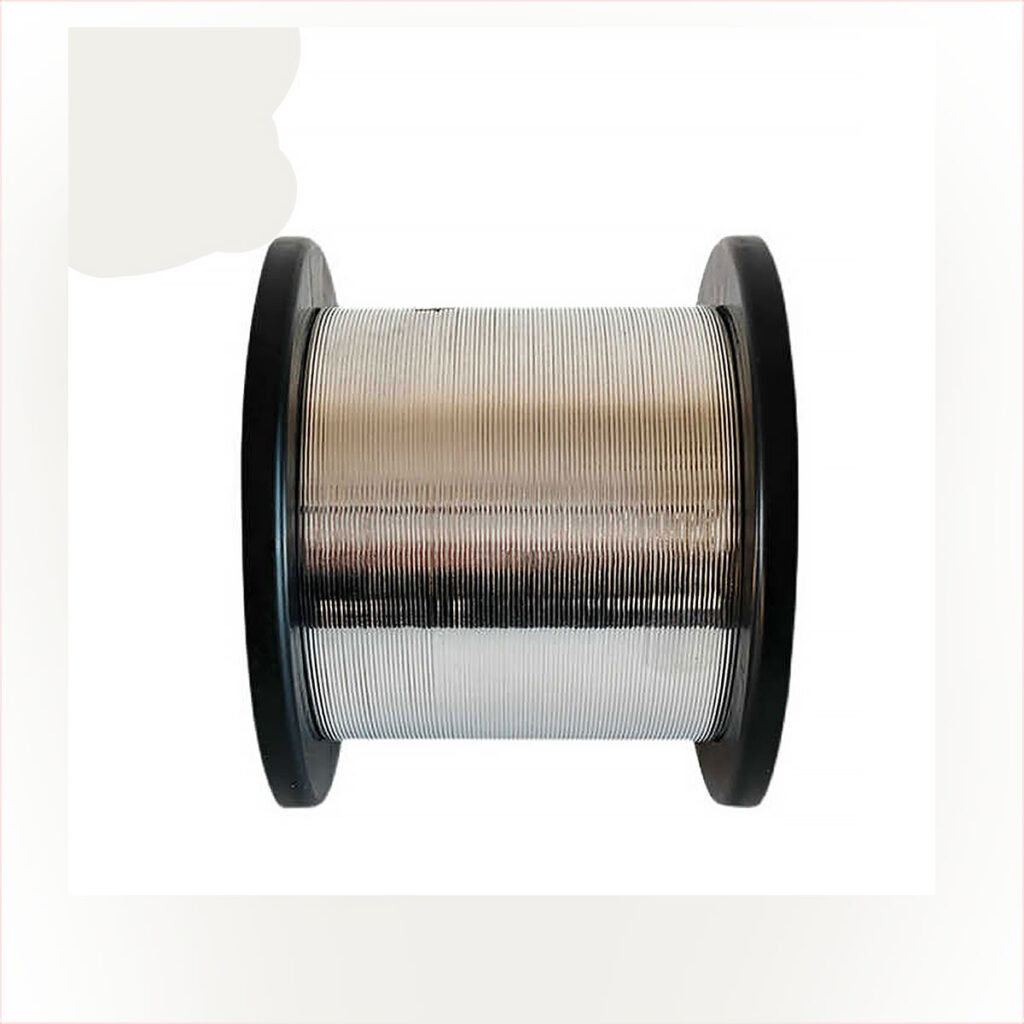

Supplied on spools (HKV 160, K125, or customized) for easy integration into automated manufacturing lines |

||||||

|

|

|||||||

|

Examples of specifications for some types of Solar Ribbon |

|||||||

|

|

|||||||

|

Ribbon Type Flux Pen |

|||||||

|

|||||||

|

|

|||||||

|

1 |

Round welding wire, copper base for electrical use, made by drawing oxygen-free copper wires, annealing, and tinning. |

||||||

|

2 |

General specifications range from 0.25 mm to 0.4 mm, and special sizes can be customized. |

||||||

|

3 |

Copper base specifications range from 0.23 mm to 0.37 mm, and the tin layer thickness (single side) ranges from 0.012 mm to 0.017 mm. |

||||||

|

4 |

Electrical conductivity (59.6 × 10⁻ S/m). |

||||||

|

5 |

Yield between 55 and 70. |

||||||

|

6 |

Specializing in the production of lead- and silver-based, lead-free, and lead-free photovoltaic welding belts. |

||||||

|

|

|

||||||

|

Technical Specification |

|||||||

|

Large module welding tape (sultable for solar large module) |

|||||||

|

Copper base |

Electric Park copper wire rolling or T2 copper strip slitting |

||||||

|

Copper substrate resistivity |

p≤0.01720mm2/m |

||||||

|

Solder composition |

62%Sn36%Pb2%Ag |

||||||

|

Sn40%60% Pb |

|||||||

|

60% Sn40% Bi |

|||||||

|

97% Sn3%Ag |

|||||||

|

Tin layer thickness |

10µm -40µm, uniform on both sides |

||||||

|

Thickness tolerance |

≤0.008 |

||||||

|

Width tolerance |

The rolled products ≤0.1mm – Slitting Commodities ≤0.005mm |

||||||

|

Elongation |

the soft state ≥20% – Semi-soft ≥15% |

||||||

|

Product specifications |

Width 1.0mm -2.5mm, Thickness of 0.08 mm 0.25 mm. |

||||||

|

Packing |

4Kg, 8Kg two kinds of l-wheel, suitable for automatic welding machine, no break in the middle; Can also cut for customers, carton packaging |

||||||

|

Material |

Sn Pb |

||||||

|

Diameter |

1.0mm – 2.5mm |

||||||

|

Melting point |

international standard |

||||||

|

Weight |

0.5kg/4Kg/8Kg |

||||||

|

Flux Content |

1.8%-2.2% |

||||||

|

|

|||||||

|

Interconnection Ribbon, Busbar |

|||||||

|

|||||||

|

|

|||||||

|

Technical Specification |

|||||||

|

1 |

Specified use |

||||||

|

Interconnection ribbons are used to connect front bus bars of one cell to the corresponding rear bus bars of the next cell to achieve a series connection, Busbar are installed around the perimeter of the solar panels; PV bus bar connects interconnect ribbon to the junction box |

|||||||

|

2 |

Physical Characteristics: |

||||||

|

Ribbon width |

1mm-3mm |

||||||

|

Ribbon thickness |

0.2 mm |

||||||

|

Busbar width |

5 ~ 6 mm |

||||||

|

Busbar thickness |

0.1mm-0.5mm |

||||||

|

Coating Thickness |

10um-40um |

||||||

|

Coating tolerance |

10%-30% |

||||||

|

Lead free solder alloys |

Sn 100% Sn 96.5%, Ag3.5% |

||||||

|

Leaded |

Sn 60%, Pb 40% Sn 62%, Pb 36%, Ag 2% |

||||||

|

Copper |

|||||||

|

Resistivity |

0.02Ω.mm2 |

||||||

|

Electrical Conductivity |

100% |

||||||

|

Purity |

99.9% |

||||||

|

Thickness |

0.2mm |

||||||

|

3 |

Mechanical characteristics: |

||||||

|

Tensile strength |

160N/mm2 |

||||||

|

Yield strength |

70N/mm2 |

||||||

|

Elongation |

25% |

||||||

|

Fusion temperature of the tin |

<220° C |

||||||

|

Camber |

8mm/ m |

||||||

|

|

|||||||

|

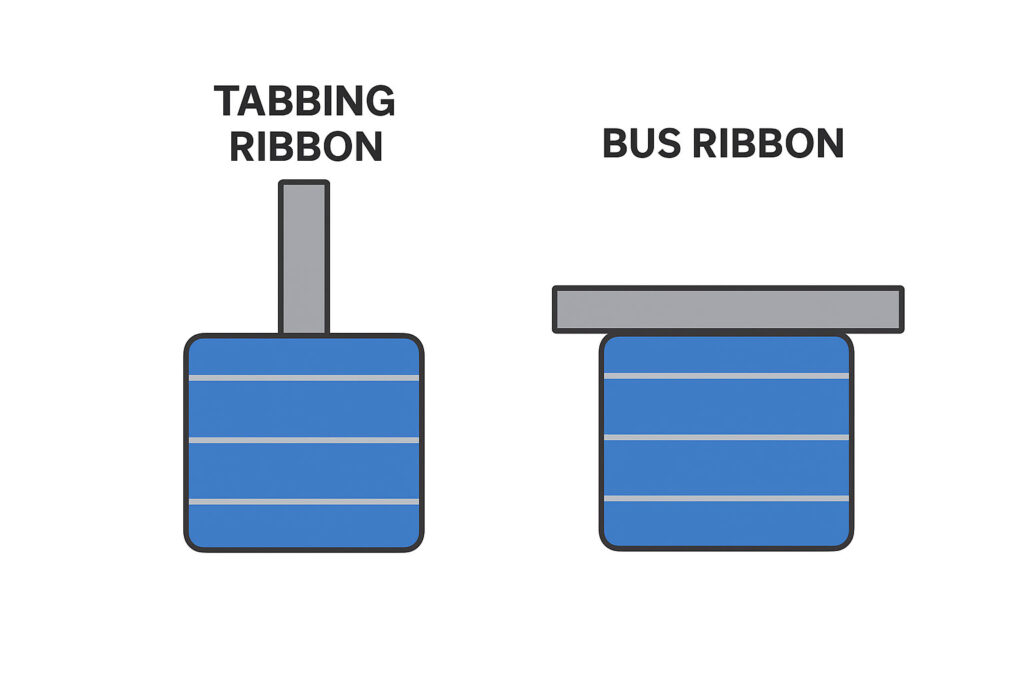

Comparison between Tabbing Ribbon and Bus Ribbon |

|||||||

|

Feature / Property |

Tabbing Ribbon |

Bus Ribbon |

|||||

|

Function |

Connects individual solar cells in series |

Collects current from multiple cell strings and carries it to the junction box |

|||||

|

Width |

Narrow (≈ 1.0 – 3.0 mm) |

Wider (≈ 3.0 – 7.0 mm) |

|||||

|

Thickness |

Thin (≈ 0.08 – 0.25 mm) |

Thicker (≈ 0.20 – 0.50 mm) |

|||||

|

Current Capacity |

Handles lower current per cell string |

Handles higher total current for the whole module |

|||||

|

Flexibility |

More flexible, easier to solder between cells |

Less flexible due to larger cross-section |

|||||

|

Position in Module |

Runs across the surface of individual cells |

Runs across the module, connecting multiple strings |

|||||

|

Main Purpose |

Interconnection between cells |

Power collection and transmission |

|||||