Description

|

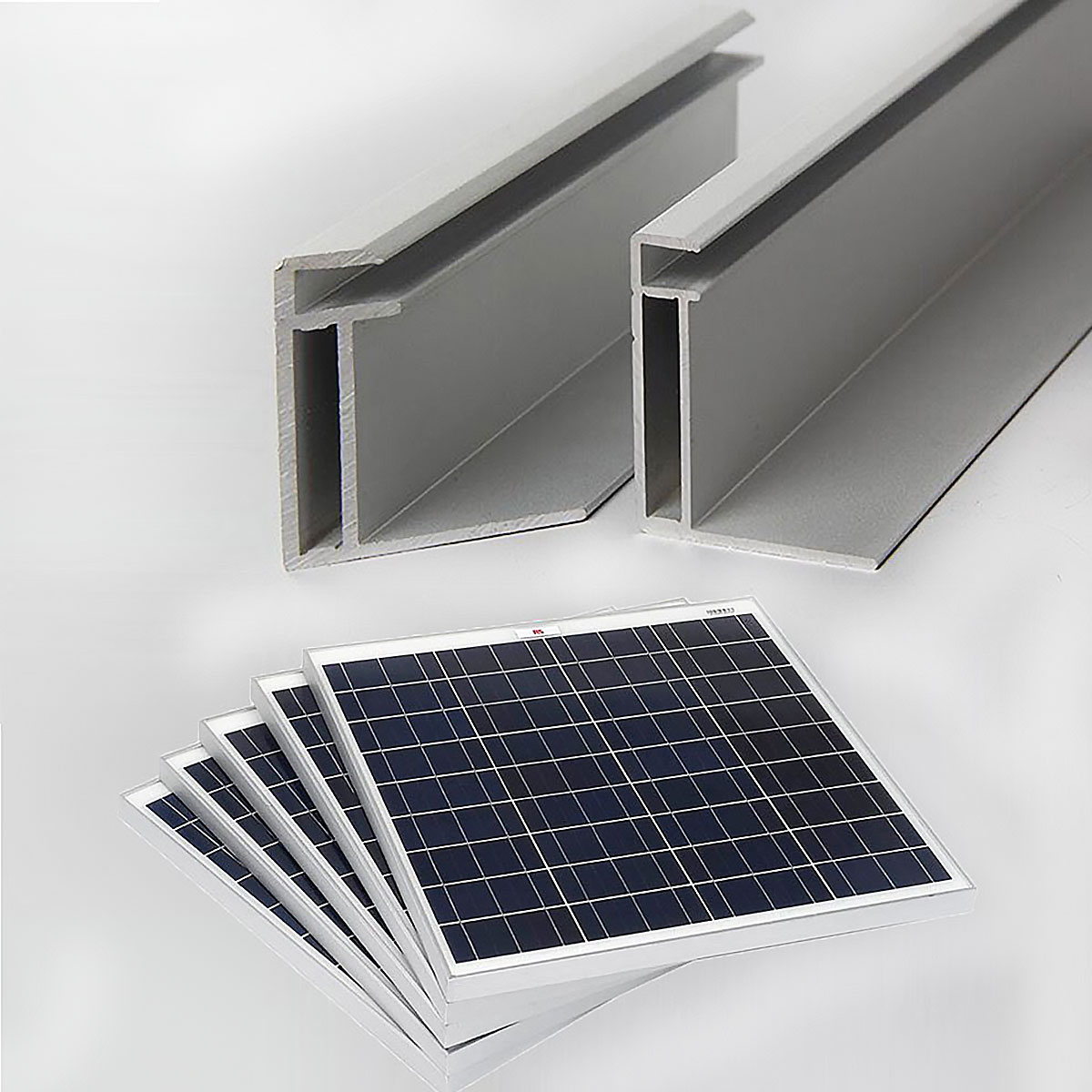

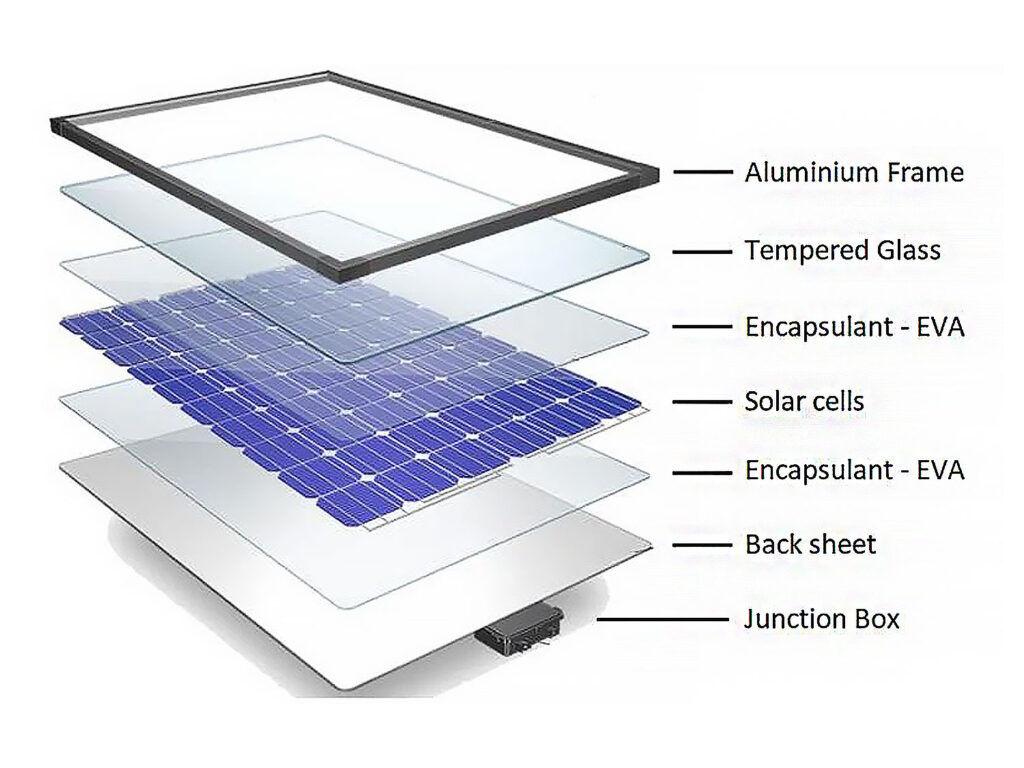

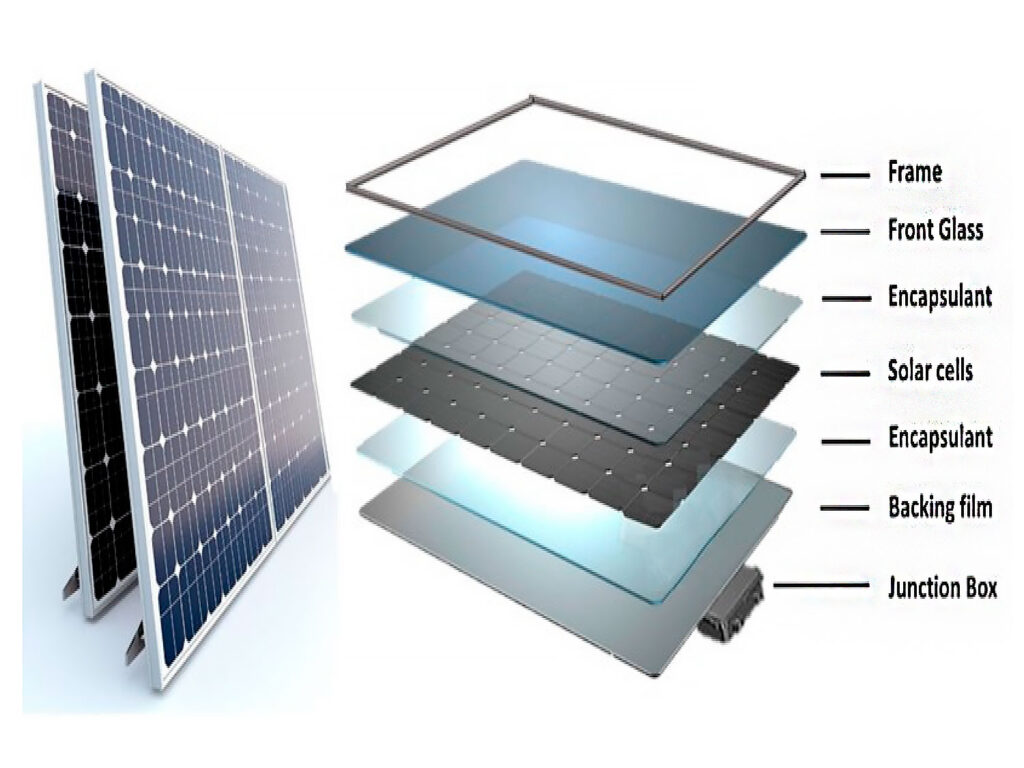

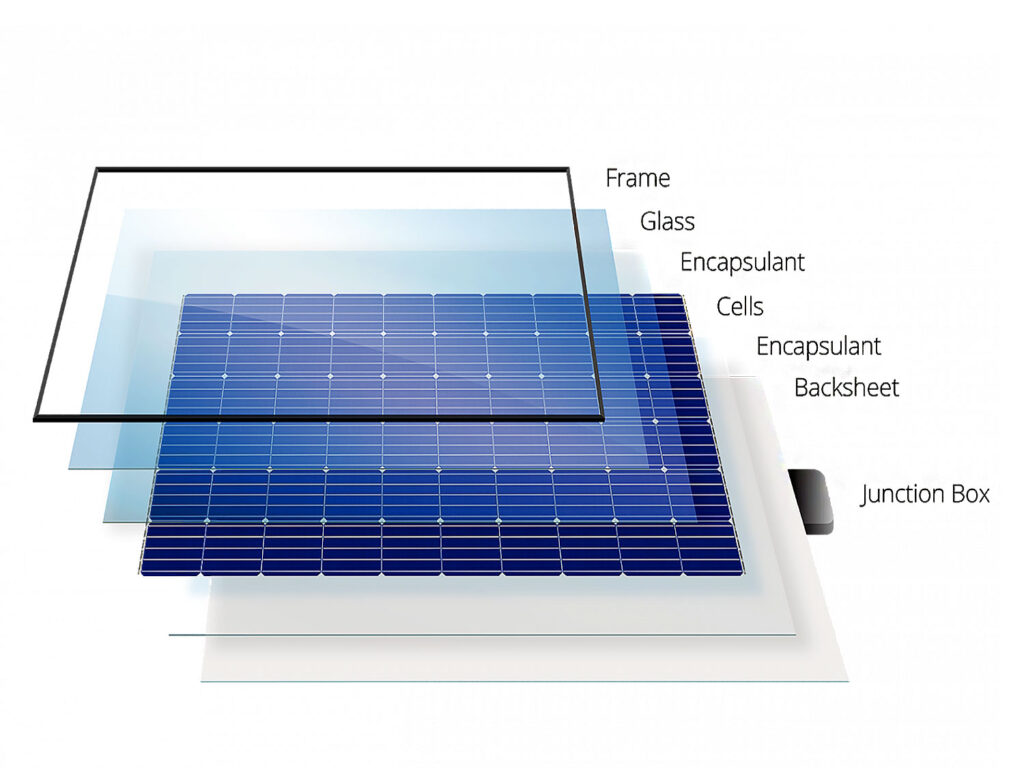

General Specifications about Solar Frame |

||||||||||||||||||

|

– |

Functions of a frame in solar panels: |

|||||||||||||||||

|

– |

Providing durability and structural support for the solar panel. |

|||||||||||||||||

|

– |

Facilitating installation on structures and scaffolding. |

|||||||||||||||||

|

– |

Protecting the edges of the glass and internal components from impact. |

|||||||||||||||||

|

– |

Improving water drainage to reduce dirt and water accumulation. |

|||||||||||||||||

|

Common Specifications |

||||||||||||||||||

|

1 |

Common Specifications |

|||||||||||||||||

|

– |

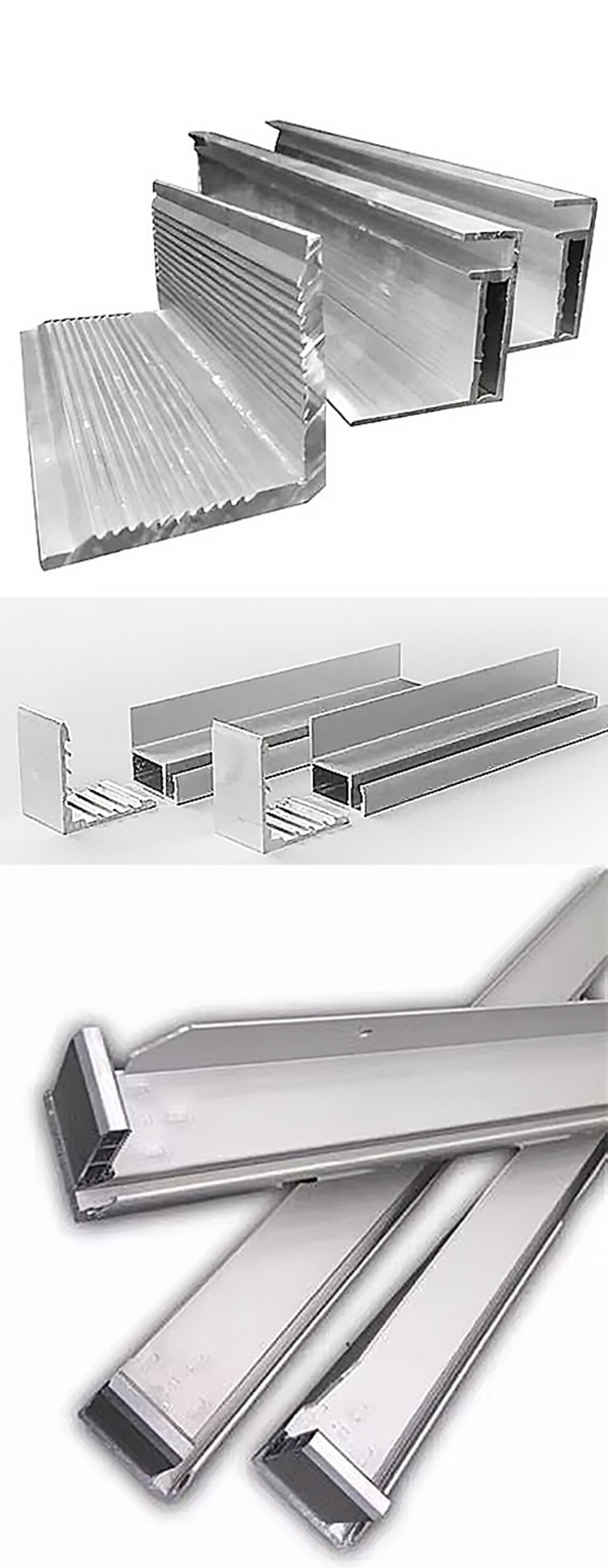

Material: Aluminum alloy (e.g., 6061, 6063, 6005). |

|||||||||||||||||

|

– |

Frame Dimensions: Vary based on the solar panel size and manufacturer, but common examples include: 33x18mm, 40x35mm, |

|||||||||||||||||

|

– |

Slot Size: The channel or groove within the frame where the glass and other components are secured (e.g., |

|||||||||||||||||

|

– |

Thickness: Refers to the height of the frame’s profile (e.g., 33mm, 40mm). |

|||||||||||||||||

|

– |

Color: Typically silver or black. |

|||||||||||||||||

|

– |

Surface Treatment: Anodizing is a common process to enhance corrosion resistance and durability. |

|||||||||||||||||

|

– |

Certifications: ISO, ROHS, SGS. |

|||||||||||||||||

|

– |

MOQ: Minimum Order Quantity (e.g., 500 sets). |

|||||||||||||||||

|

– |

Suitable Glass Thickness: Specifies the maximum thickness of glass the frame can accommodate (e.g., 3.2mm). |

|||||||||||||||||

|

2 |

Key Considerations: |

|||||||||||||||||

|

– |

Corrosion Resistance: Aluminum alloys are chosen for their resistance to rust and environmental factors. |

|||||||||||||||||

|

– |

Strength and Durability: The frame needs to be strong enough to support the weight of the solar panel and withstand wind and |

|||||||||||||||||

|

– |

Mounting Compatibility: The frame should be designed for easy and secure mounting to the intended structure. |

|||||||||||||||||

|

– |

Compatibility with Solar |

|||||||||||||||||

|

3 |

Additional Notes: |

|||||||||||||||||

|

– |

Some solar panel frames may be designed with specific features like pre-drilled holes for mounting or integrated wiring channels. |

|||||||||||||||||

|

– |

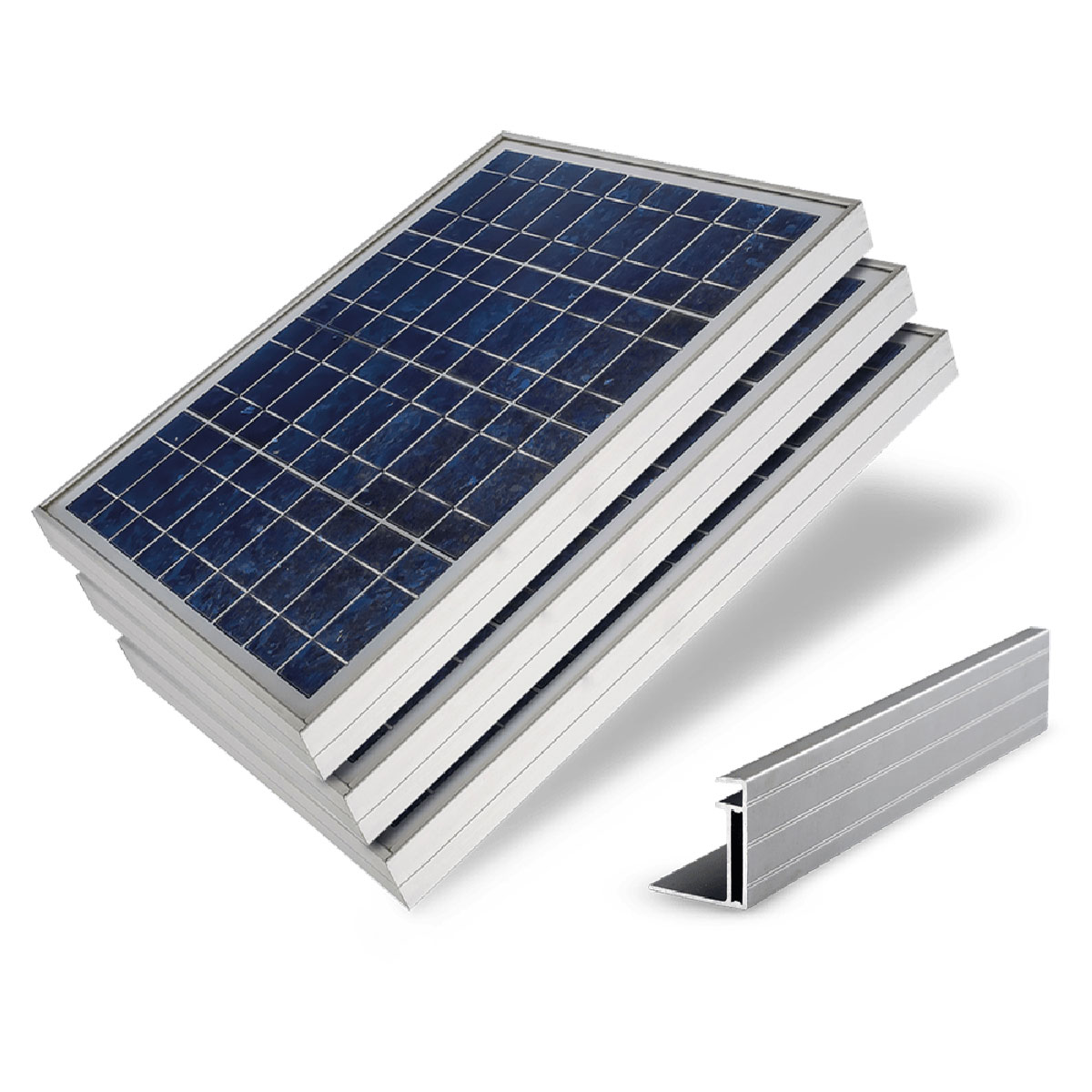

Frames are often designed to be stackable for efficient transportation and storage. The frame can be customized with various surface treatments like anodizing or powder coating. |

|||||||||||||||||

|

4 |

Characteristics of a good frame: |

|||||||||||||||||

|

– |

Made of corrosion-resistant aluminum. |

|||||||||||||||||

|

– |

Lightweight yet mechanically strong. |

|||||||||||||||||

|

– |

Compatible with various mounting systems. |

|||||||||||||||||

|

– |

Resistant to harsh weather conditions such as wind, snow, and rain. |

|||||||||||||||||

|

5 |

Frame shapes: |

|||||||||||||||||

|

– |

Sharp edge frame – More rigid. |

|||||||||||||||||

|

– |

Rounded edge frame – Preferred in some aesthetic designs or to reduce cable damage. |

|||||||||||||||||

|

|

||||||||||||||||||

|

Examples of specifications for some types of Solar Encapsulant |

||||||||||||||||||

|

|

||||||||||||||||||

|

Datasheet of Solar panel )AL–frame( |

||||||||||||||||||

|

||||||||||||||||||

|

|

||||||||||||||||||

|

Technical Specification |

||||||||||||||||||

|

Grade |

6063 |

Temper |

T5 |

Type |

Profile |

|||||||||||||

|

Brand Name |

— |

Thickness |

0.4mm-50mm |

Cross-section |

8mm-650mm |

|||||||||||||

|

Surface Treatment |

Customization |

Alloy or not |

Is Alloy |

— |

— |

|||||||||||||

|

Loading port |

Shanghai |

Trade term |

FOB CIF CNF |

sample |

free and fast |

|||||||||||||

|

Advantages |

1 |

Good quality in material |

||||||||||||||||

|

2 |

Excellent surface finish |

|||||||||||||||||

|

3 |

Competitive price |

|||||||||||||||||

|

Certificate and Standard |

1 |

ISO9001-2008/ISO 9001:2008. |

||||||||||||||||

|

2 |

CQM Certification. |

|||||||||||||||||

|

3 |

SGS, CE, BV, JIS, AS, available. |

|||||||||||||||||

|

Guarantee |

Surface color can be stable for 10~20 years indoor using. |

|||||||||||||||||

|

Lead Time |

Mass Production: 10-20days. |

|||||||||||||||||

|

Settlement Terms |

Charge by final actual weight or by drawing theoretical weight. |

|||||||||||||||||

|

Aluminum Alloy Chemical Composition |

||||||||||||||||||

|

Alloy |

Element |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

|||||||||

|

6063 |

Standard |

0.2-0.6 |

≤0.35 |

≤0.1 |

≤0.1 |

0.45-0.9 |

≤0.1 |

≤0.1 |

≤0.1 |

|||||||||

|

Testing result |

0.483 |

0.143 |

0.019 |

0.017 |

0.554 |

0.0052 |

0.001 |

0.0029 |

||||||||||

|

|

||||||||||||||||||

|

Comparison Between Framed and Frameless |

||||||||||||||||||

|

Feature |

Framed Panels |

Frameless Panels |

||||||||||||||||

|

Aesthetic Appearance |

Traditional look with visible aluminum frame |

Sleeker, modern appearance – glass only |

||||||||||||||||

|

Weight |

Relatively lighter |

Slightly heavier due to double glass design |

||||||||||||||||

|

Installation |

Easier to install using standard mounting clamps |

Requires specialized mounting systems |

||||||||||||||||

|

Mechanical Protection |

Good protection for edges and corners |

Edges more exposed to damage |

||||||||||||||||

|

Water/Dust Drainage |

Frame may trap water and dust in some cases |

Allows smooth flow of water and dust |

||||||||||||||||

|

Durability in Harsh Weather |

Very good, especially against wind and snow |

Also durable, but depends on glass quality and mounting |

||||||||||||||||

|

Cost |

Generally lower cost |

Slightly more expensive due to materials and mounting |

||||||||||||||||

|

Common Usage |

Widely used in residential and commercial systems |

Often used in aesthetic projects or harsh environments |

||||||||||||||||